Woodonglass

Supreme Mariner

- Joined

- Dec 29, 2009

- Messages

- 25,932

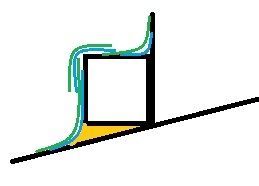

Here's how I'd recommend doing it. Others might do it differently. I'd use Titebond III wood glue and glue the 3/4" pieces of plywood together to make the blocks. I'd then use a table saw to cut the angle to closely mimic the angle of the hull. ( You might not need to do this if the angle isn't too bad. The PB and fill it in and make up the difference. It's up to you) Epoxy and Poly don't like each other so don't use it. Just coat the Blocks in Poly really well after they're fabricated and then bed them in a some PB and get em level and at the correct Height. Then apply more resin and attach them to the hull with 3-4 layers of 1708 going over the top if you can. You can use CSM between the layers of 1708 but really not needed. Then use the Gel coat to finish it off and make it PURDY!!!! That's the Old Dumb Okie's way of doing it!!!

Last edited: