classiccat

"Captain" + Starmada Splash Of The Year 2020

- Joined

- Dec 20, 2010

- Messages

- 3,412

nice progress... and nice tractor!

is that an Onan powered Suburban?

is that an Onan powered Suburban?

Thanks guys-- the seamstresses told me that this is the last job for them . LOL . I will buy a used upholstery sewing machine when I sell this beauty but I hope that's not for a little while . Off to the next project right after that so not too sorry to see her go just want to play with her for a bit first.

My old 1974 Sears SS16 has the original Onan engine and although it smokes a bit and drinks the oil , I still cut the grass and was plowing with it last year. Could use an engine rebuild or swap it out for an opposed twin Briggs but would like to see the Onan stay. We will see , got other fish to fry for now .

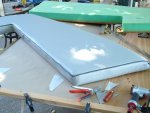

Gettin ready for a skinnin ---------

I will go through the links and see what they got . I believe Onanparts are the ones I had a problem with. Never again.