Well, pulled the manifold off, pretty easy process.

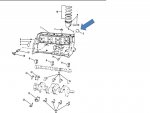

Cracked block......

Looks like someone had put something in the motor to try and seal it in the past as a hard substance looks like it had oozed out of the crack at some point in the past.

Now, repair options.

I have read some other stuff online that this kind of crack, that does not cause water in the oil can be repaired with welding, or even JB weld. I only have $2000 ish in this boat so replacing the block is a last resort option.

I am also going to call the guy that sold it to me and give him a piece of my mind about selling a boat with obviously known issues as "Lake Ready". I swear, when I sold my old boat I tried to outline every last detail and quirk the boat had so the new owner wouldn't be blindsided by anything.