Friendliest_catch

Cadet

- Joined

- May 9, 2021

- Messages

- 29

Hello all. I have another thread about the whole issue I'm going through right now but long story short the portside motor mount stringer area was poorly constructed and had a crack near bottom of bilge. Along with that there was water leaking into the wood through motor mount lag bolt holes. Wood rotted on portside requiring removal of over 2 ft of rotten wood. Starboard is good with some evidence of dry rot in the bad areas, but I will be using west marines solution to drill several holes and saturate the existing wood as it has not delaminated and it is structurally sound..

Removing all stringers and redoing with seacast isn't viable for this boat. It's a freshwater lake boat only and I don't have the money or time to do a complete rebuild.

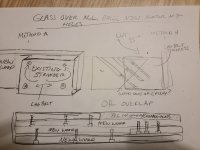

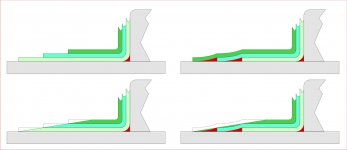

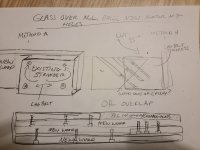

I want to take off all fiberglass where the old stringers and mounts were and rebuild the stringer with wood using lag bolts through existing good wood and then buddy up other wood to that structural member. I will fill all spaces with either a structural putty or some kind of fiberglass slurry and then once cured glass over whole assembly.

I have a few main questions.

One, are stainless lag bolts over kill? I feel that several aligned in the old 2x6 with a new 2x6 is the best structural answer.

Two, I drew out some methods of how to do it. Should I cut at 45 and mount stringer in line ? Should I cut and 45 and buddy up with lag bolts?

Three, I have some dried out redwood from a fencing project that has been drying for over 7 months....is that sufficient? I'm doing research on what wood to use currently.

Four and lastly, is this repair safe? I feel that properly constructed and reglassed correctly it will be even better than what was in there before if I make the glass even thicker...the original stringers were nailed together so that says something!!

Here are some photos of the project and my theory of repair. Reading up on as much repair info as I can the past week has led me here.

The photo of me holding the wood shows a section of good wood I removed that was next to main stringer to illustrate the integrity of what is left.

Removing all stringers and redoing with seacast isn't viable for this boat. It's a freshwater lake boat only and I don't have the money or time to do a complete rebuild.

I want to take off all fiberglass where the old stringers and mounts were and rebuild the stringer with wood using lag bolts through existing good wood and then buddy up other wood to that structural member. I will fill all spaces with either a structural putty or some kind of fiberglass slurry and then once cured glass over whole assembly.

I have a few main questions.

One, are stainless lag bolts over kill? I feel that several aligned in the old 2x6 with a new 2x6 is the best structural answer.

Two, I drew out some methods of how to do it. Should I cut at 45 and mount stringer in line ? Should I cut and 45 and buddy up with lag bolts?

Three, I have some dried out redwood from a fencing project that has been drying for over 7 months....is that sufficient? I'm doing research on what wood to use currently.

Four and lastly, is this repair safe? I feel that properly constructed and reglassed correctly it will be even better than what was in there before if I make the glass even thicker...the original stringers were nailed together so that says something!!

Here are some photos of the project and my theory of repair. Reading up on as much repair info as I can the past week has led me here.

The photo of me holding the wood shows a section of good wood I removed that was next to main stringer to illustrate the integrity of what is left.