Sounds like I get to redo the cable job over the offseason... Yay

Not sure what went wrong other than my setup having a 90 degree bend past the shift boot and such likely bending the rod (and possibly ripping the liner) on insertion. I did use a genuine Mercruiser cable kit... and did back off the set screw before safety wiring.

And now that we're in the offseason, I redid it this evening!

This time I used a Sierra kit. Partially to save a bit of money, partially to see if their product would work out better.

There were a few differences. One is that they're using a different style safety wire lug on the cable fork (single post instead of a hoop)... didn't get a pic. No biggie though, just figure-8 the wire instead of a loop.

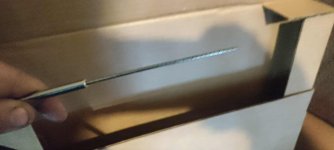

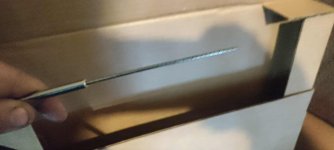

The other difference is that instead of a coated inner wire with a metal sleeve on the end, the wire is uncoated with no cap, yet smoothed on the outside:

I used to do a lot of bicycle mechanic work, so I'm used to dealing with un-coated cables. Just grease the snot out of them and they do OK. Given that the metal sleeve on the Quicksilver cable banana'd on me (and likely a good part of why I was having binding), I'm calling this an improvement for my specific situation.

Another deviation is that I installed the cable bushing from the outside... the inside of the transom plate on my boat is inaccessible (due to having a sun deck with a shift cover, not a doghouse). Due to this poor access, it took some creativity to be able to get the chafe guard on the cable down there; the trick was to install the first few twists higher up on the cable, then slide it down the cable and wrap the rest of the way with the drive turned all the way to starboard to push the cable as far into the bilge as it will go.

Speaking of the cable, I did some looking and it seems the original (to me) cable routing wasn't correct and likely another cause of the binding. Here's what I have currently:

That's not super clear, so here's the old and new routing drawn on top:

Red is the old routing... took a hard 90

° bend coming out of the transom and ran between the transom and the Y-pipe. The new is in green; the bend is a lot less severe by running between the Y-pipe and the flywheel cover. I did notice some reduction in cable resistance with the new routing, so I'm rolling with it.

On re-assembly, I discovered that I couldn't reach reverse gear at all... turns out somehow I managed to pop the shift roller off the fork. Got to pull the drive back off and try again... At least the gasket somehow survived the unplanned second removal.

Once I had the linkage issue fixed, I confirmed that the cable isn't binding (some resistance, but nothing wild like I had before) and I was also able to get the drive to fully catch both sides of the shift dogs. Had to go with max slot adjustment though. I think the shift "foot" splines may be a bit worn; I didn't take a protractor to it but it looks like it's barely within the 12

° spec. Wasn't interested in popping the drive apart... so I'll keep an eye on it.

This spring, we shall see...