Re: lync and synce confusion , please help

OK, guess I'll jump in here and give my 2c. I avoided it because 1995 is a bit new for me, and I don't want to give bad advice. HOWEVER, the procedure on an older motor is this:

1. Make sure all carburetor throttle shafts begin to open at precisely the same time. Adjust linkage between the carbs to achieve this if necessary.

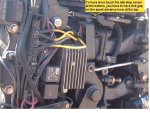

2. Disconnect the remote cable to get it out of the way.

3. Move the throttle cam so that the embossed mark aligns with the roller. The roller should just begin moving at this point. If it does not, loosen the screw retaining the roller arm to the center carburetor throttle shaft, and rotate the roller arm back or forth to achieve just starting to move when they align. Re-tighten the screw and recheck operation.

4. Connect a timing light and start the engine. Move timer lever back or forth to achieve a certain specified pick-up degrees. See, that is what I don't know for that motor. There may be a decal???? Example: In 1972 it was 8 degrees. Adjust the idle speed screw so that the specified degrees holds with lever against the idle speed screw.

5. Stop motor, and check the cam to carburetor mark position with the throttle against the idle speed stop. Roller should be centered on the embossed mark. If not, then remove the horizontal link between the throttle lever and the cam, and adjust the length so that the alignment is achieved. Reconnect the link.

6. Start motor, and adjust idle speed screw for correct RPM, in gear, on a boat, on the lake. Again, I don't know the spec speed. In 1972 it was 650 RPM

7. Ok if the full advance screw was messed with, you will also have to adjust the full spark advance screw. Let's hope nobody messed with that. You haven't, have you?

8. Reconnect throttle cable and adjust the cable to fit the motor. NEVER readjust the motor to fit the cable!!!!

Hope this is clear. Good luck. BTW, note that certified outboard technicians earn their pay. Everybody assumes they are crooks. Not fair.

OK, guess I'll jump in here and give my 2c. I avoided it because 1995 is a bit new for me, and I don't want to give bad advice. HOWEVER, the procedure on an older motor is this:

1. Make sure all carburetor throttle shafts begin to open at precisely the same time. Adjust linkage between the carbs to achieve this if necessary.

2. Disconnect the remote cable to get it out of the way.

3. Move the throttle cam so that the embossed mark aligns with the roller. The roller should just begin moving at this point. If it does not, loosen the screw retaining the roller arm to the center carburetor throttle shaft, and rotate the roller arm back or forth to achieve just starting to move when they align. Re-tighten the screw and recheck operation.

4. Connect a timing light and start the engine. Move timer lever back or forth to achieve a certain specified pick-up degrees. See, that is what I don't know for that motor. There may be a decal???? Example: In 1972 it was 8 degrees. Adjust the idle speed screw so that the specified degrees holds with lever against the idle speed screw.

5. Stop motor, and check the cam to carburetor mark position with the throttle against the idle speed stop. Roller should be centered on the embossed mark. If not, then remove the horizontal link between the throttle lever and the cam, and adjust the length so that the alignment is achieved. Reconnect the link.

6. Start motor, and adjust idle speed screw for correct RPM, in gear, on a boat, on the lake. Again, I don't know the spec speed. In 1972 it was 650 RPM

7. Ok if the full advance screw was messed with, you will also have to adjust the full spark advance screw. Let's hope nobody messed with that. You haven't, have you?

8. Reconnect throttle cable and adjust the cable to fit the motor. NEVER readjust the motor to fit the cable!!!!

Hope this is clear. Good luck. BTW, note that certified outboard technicians earn their pay. Everybody assumes they are crooks. Not fair.