hayko1971

Starmada Splash of the Year 2015

- Joined

- May 24, 2013

- Messages

- 448

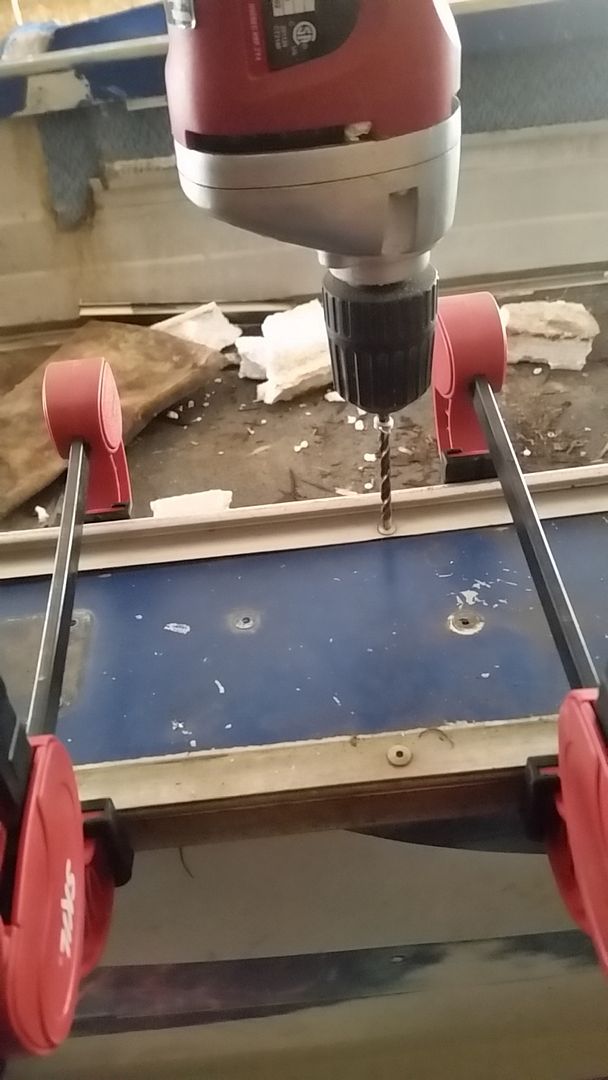

yes, I have to clean it all up yet and fill holes etc... I have a bunch of holes on the tops of the gunnals that are from removed snaps. I plan to fill them with JB weld.

When people do that, do they just use regular JB weld or a marine formulation?

When people do that, do they just use regular JB weld or a marine formulation?