Quick update . . .

In my research, I came across a bracket that was made for a Chaparral 327 SSX, which is essentially Chaparral's version of my boat ( mid-cabin bowrider). The Admiral and I looked at a 327 SSX when we were shopping for the CY338. The Chappy got a thumbs down from the Admiral because of an awkward cabin layout which would result in frequent head-banging. I gave it a thumbs down for the raw water cooled engines.

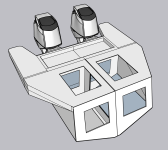

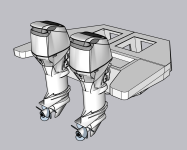

Anyway . . . here is a link to the bracket and some pictures . . .

https://weldingworldinc.com/collect...m-high-flotation-twin-outboard-engine-bracket

About $9K with shipping, which is a good reference point for my planning/budgeting.

The Chappy bracket is a bit small for my boat, but the concept is about the same, except for attaching the top of the bracket to the underside of the platform.

I'm not sure if there is a significant reason that one would not want to provide some attachment to the swim deck, but something to consider pro's/con's of doing such. Perhaps an issue of trapping water in between the top of the bracket and the underside of the swim deck. I might alter my design accordingly and go with an easier approach.

.

About a 2-3" air gap between the swim deck and the bracket . . .

.

I also noticed in the description, that 6061 T6 and 5052 H32 aluminum were used in fabricating the bracket. It seems like 6061 is a step up from the 5083 aluminum used in some brackets.

@Scott Danforth , any comments on the type of aluminum and the air gap?