Hello thanks to all for commenting on my post. So I was in contact with another guy on a different forum and he actually spent some time with me to give me input on the issues that could cause the shaft foot to not engage reverse.

The shaft foot actually does engage gears if I remove the Mercruiser Upper Lever Arm 45518A3, which I did, then mounted the drive back up without that arm shaft and after raising the drive up I could get my hand inside to turn the shaft foot manually and it was engaging forward and reverse fine. It was a weird experience being down there with the motor running trying to engage the gears. But as I said I bought a new lever arm 45518A3, on mine the roller plastic was a bit chewed up all around. I put it back up again with the new upper shaft arm this time and no reverse, well a bit of reverse but not a permanent solution, mostly gears grinding noise. So I got tired of the back and forth and used a bit of Eastern European ingenuity and Jerry Rigging(back in the old country you solved everything with a hammer

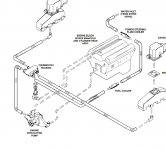

)) and I actually grinded off a portion of the shaft arm that was touching against the wall of the drive, say 3/16 or so. I also grinded part of the cable F looking shift mechanism that the arm moves back and forth(don't remember the name of it right now). It's cast aluminum so it grinded pretty good. Well guys sure enough I put it back together for the 3rd time today and I did get reverse on the short shift cable by pulling on it. Before I could not get it to engage the reverse, just getting the gear grinding noise and no full engaging. So reinstalled the drive and I torqued the 6 bolts reinstalled the hydraulic arms for the trim, I must say it now takes me 2 minutes to remove it all and 4 to put it back. I adjusted the short shift cable to the 6 inches, and then I had a little trouble getting the remote cable to actually engage reverse. But after loosening the 7/16 rear anchor pin(that the head of the lower shift cable attaches to) and moving it a little more than half way up it's slot from the book recommendation of all the way down, it all started to work. I finally got reverse and forward acting the same and engaging before throttle was engaged. the remote cable I adjusted by feel but it is as close to the proper adjustment as it can be. And the cut off switch doesn't get activated to shut off the motor either after some adjustment. The real test will be on water at WOT, but I think no matter what it will still be ok.

Bottom line something moved, got bent the first time I installed the whole thing and the lower shaft foot got ridden by the shaft upon the removal or install of the drive early on. Maybe!

Even though before that I didn't have a smooth reverse engagement either. So maybe the problem was just exacerbated by the two shafts riding each other. Who knows, but the damn thing is great now, quick engagement smooth gears and hard work finally paying off. Remember this whole project started with hydro locking the engine in the parking lot last November. So I had to rebuild the 2BBL carb, remove the manifolds and change flappers, clean manifolds and risers, change rubbers at the elbows,

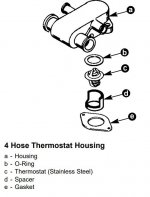

new gaskets, then new circulation water pump which was actually bad. New raw water pump in the drive, old one looked good though, but did not have water coming out from exhaust and engine was overheating. New seals on the upper drive plus to 2 new bearings on the main shaft that needed to be preloaded with a dial torque wrench. New bellows, hoses, main bearing, and last but not least the gear fluid, and lots of greases.

**** that's a lot of work and I am not so certain it all needed to be done.

But hey I did it myself and saved some money that way.

I will post as soon as I put it on water. I am beat.