ratdude747

Petty Officer 1st Class

- Joined

- Sep 30, 2023

- Messages

- 221

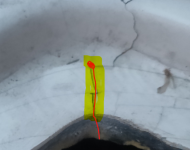

While replacing some bungee cords on my bow riding seats, I found a stress crack in the seat opening:

Specifically the crack radiating from the hull edge (the other is just in the Gel coat AFAIK). It goes all the way through the wood and inner glass.

How should I mitigate this? Not looking for a cosmetic repair (as it's hidden under a seat cushion), but I also don't want the damage to continue as that's my wife's favorite seat. Preferably a repair I could knock out over an evening. Marine-tex? JB Weld?

Specifically the crack radiating from the hull edge (the other is just in the Gel coat AFAIK). It goes all the way through the wood and inner glass.

How should I mitigate this? Not looking for a cosmetic repair (as it's hidden under a seat cushion), but I also don't want the damage to continue as that's my wife's favorite seat. Preferably a repair I could knock out over an evening. Marine-tex? JB Weld?