I could use some suggestions for removing a stuck gimbal bearing. Water got into the U-Joint bellows and onto the bearing and it rusted. I did not think that the rust was that extensive because the boat was running fine but had a slight rumble in the bearing. The water getting into the bellows was also leaking into the bilge and that became the motivation to replace the bearing. (There is also other work I'm doing due to the leak. See my other posts)

I have tried 3 methods so far and have not been successful:

1) Slide hammer

This has 3 jaws that go through the bearing and expand outward with a collar. It grabs the bearing from the back. You slide the weight hard and fast against the stop to bang the bearing out. The weight/slide weighs 2 ½ lbs. That did not work.

2) Bearing puller

I also have a custom bearing puller with a long shaft, a way to brace it against the gimbal assembly and a nut that you turn. It works just like the official tool. See pictures. That did not get the bearing out either but there were 2 pops, so something may have moved. I was torquing on the nut to maybe 50 ft-lbs. (pretty hard with a 10 inch Crescent wrench) Never having done this before and not wanting to damage anything like the gimbal, I stopped.

3) Heating the housing with a torch

This is a Propane canister with the torch screwed on. I heated the housing for a couple of minutes and then alternated between the torch, slide hammer and bearing puller. Since I had been spraying the bearing with “Big Blaster” rust dissolver, I did read the label and it did NOT say that it was flammable. I had a fire extinguisher next to me just in case. I also ran the blower first. Heating may have done a little but it did not come out.

4) Drill out the bearing

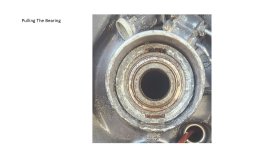

My next step is to drill out the bearing. I have been told that works but I want to be certain that I know exactly what to drill. Below is a picture of the bearing with the parts numbered.

Which one do I drill out? Any other suggestions?

Thank you

I have tried 3 methods so far and have not been successful:

1) Slide hammer

This has 3 jaws that go through the bearing and expand outward with a collar. It grabs the bearing from the back. You slide the weight hard and fast against the stop to bang the bearing out. The weight/slide weighs 2 ½ lbs. That did not work.

2) Bearing puller

I also have a custom bearing puller with a long shaft, a way to brace it against the gimbal assembly and a nut that you turn. It works just like the official tool. See pictures. That did not get the bearing out either but there were 2 pops, so something may have moved. I was torquing on the nut to maybe 50 ft-lbs. (pretty hard with a 10 inch Crescent wrench) Never having done this before and not wanting to damage anything like the gimbal, I stopped.

3) Heating the housing with a torch

This is a Propane canister with the torch screwed on. I heated the housing for a couple of minutes and then alternated between the torch, slide hammer and bearing puller. Since I had been spraying the bearing with “Big Blaster” rust dissolver, I did read the label and it did NOT say that it was flammable. I had a fire extinguisher next to me just in case. I also ran the blower first. Heating may have done a little but it did not come out.

4) Drill out the bearing

My next step is to drill out the bearing. I have been told that works but I want to be certain that I know exactly what to drill. Below is a picture of the bearing with the parts numbered.

Which one do I drill out? Any other suggestions?

Thank you