Lumbering_Oaf

Cadet

- Joined

- Mar 30, 2011

- Messages

- 17

So I am a New Member with a Big Project (This is going to be a long post  ):

):

I bought this boat for several reasons. I know Bayliners are not the most popular boat and have a poor reputation. Partially deserved I am sure but I believe that part the reputation was unfairly earned from them being a entry level boat bought by inexperienced boaters and they had a stretch of poor quality control in the 80' and early 90's. Any way enough of that. I wanted a boat that I could take my family of 4 out for long weekends, be able to trailer, and have a fly bridge. Those requirements really limited my choices from the get go. I can not afford 100K + for a new boat in the 26 to 30' range and a few years used are still really expensive and you can still run into a lot of unknown costly problems. I am also a pretty handy guy that enjoys working on and fixing up things so older is not a problem for me. So I was looking for a project boat that I could have fun building my way and when it was finally finished I would have something a little different, practically brand new, and have the clear title to boot. Banks and interest are bad

I stumbled across this boat in South Dakota in January It's really hard to get a good assessment of a boat and it's condition when everything is frozen. But I got the Boat and Trailer for just a little under 4K so I figured that I was in for a big project but the price of admission was right. See the first pic from the day I bought it.

It's really hard to get a good assessment of a boat and it's condition when everything is frozen. But I got the Boat and Trailer for just a little under 4K so I figured that I was in for a big project but the price of admission was right. See the first pic from the day I bought it.

I knew there was a real soft spot in front of the head door so I just knew I was going to be replacing wood. So fast forward 2 months and things finally thawed out just enough to make the trip to pick her up (see second pic on the way home).

We got her home and found that the Volvo (305 chevy) engine passed the mechanical test just find (the PO said it had been rebuilt less the 100 hours ago) started right up and has great compression. Out drive is in good working order. So far so good.

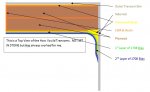

Then it was time to take a look at the soft spot in front of the head door. See pics 3 and 4 :facepalm:

We pulled the carpet to find some formica Just laying there and guess what was under that

Next post the tear down! Time to find the extent of the damage.

I bought this boat for several reasons. I know Bayliners are not the most popular boat and have a poor reputation. Partially deserved I am sure but I believe that part the reputation was unfairly earned from them being a entry level boat bought by inexperienced boaters and they had a stretch of poor quality control in the 80' and early 90's. Any way enough of that. I wanted a boat that I could take my family of 4 out for long weekends, be able to trailer, and have a fly bridge. Those requirements really limited my choices from the get go. I can not afford 100K + for a new boat in the 26 to 30' range and a few years used are still really expensive and you can still run into a lot of unknown costly problems. I am also a pretty handy guy that enjoys working on and fixing up things so older is not a problem for me. So I was looking for a project boat that I could have fun building my way and when it was finally finished I would have something a little different, practically brand new, and have the clear title to boot. Banks and interest are bad

I stumbled across this boat in South Dakota in January

I knew there was a real soft spot in front of the head door so I just knew I was going to be replacing wood. So fast forward 2 months and things finally thawed out just enough to make the trip to pick her up (see second pic on the way home).

We got her home and found that the Volvo (305 chevy) engine passed the mechanical test just find (the PO said it had been rebuilt less the 100 hours ago) started right up and has great compression. Out drive is in good working order. So far so good.

Then it was time to take a look at the soft spot in front of the head door. See pics 3 and 4 :facepalm:

We pulled the carpet to find some formica Just laying there and guess what was under that

Next post the tear down! Time to find the extent of the damage.