I started this thing like normal yesterday morning but noticed smoke was let out near the key switch. When I went to restart before taking it out to the lake, I was presented with a no start condition. I pulled one high tension plug wire at a time and connected to a chassis grounded spare spark plug and there is no spark at either cylinder.

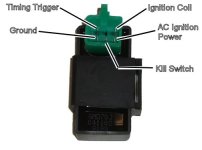

So something must have burned at the key switch creating the no spark condition. I don't know much about the key wiring. Where do I begin to look? My two coils look like this. I'm guessing this is a CDI. I see 4 wires plus ground and the plug lead on each coil. So probably a pair for AC voltage in from the stator and a pair for the trigger signal. I am a little familiar with the CDI itself but have no idea where to look from the key switch on as far as a run/stop signal. Any tips would be greatly appreciated!

So something must have burned at the key switch creating the no spark condition. I don't know much about the key wiring. Where do I begin to look? My two coils look like this. I'm guessing this is a CDI. I see 4 wires plus ground and the plug lead on each coil. So probably a pair for AC voltage in from the stator and a pair for the trigger signal. I am a little familiar with the CDI itself but have no idea where to look from the key switch on as far as a run/stop signal. Any tips would be greatly appreciated!