silveraire

Petty Officer 1st Class

- Joined

- Apr 23, 2006

- Messages

- 241

Picked up this ol' girl this spring. She was rough. What started out as project I wanted to keep cheap got a bit out of hand. So after an unplaned new Merc CT115 4 stoke and a new galvanized trailer, I needed to stop spending money. Tried to clean the old seats but the vinyl just crumbled. We wanted to keep this an all cash deal so out of cash and not wanting to finance or put anything on the cc, no new seats were in our future for now. we decided to attempt to recover the seats. This is what we started with.

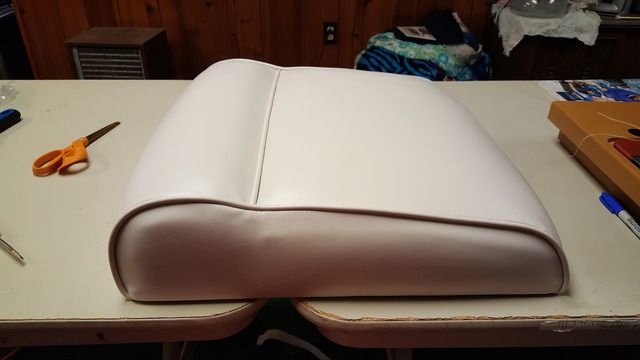

Started out with a 1950's Viking sewing machine, which did the job ok but struggled. Going through 5 layers of vinyl was going to kill it. I borrowed a family members sailrite portable walking foot sewing machine. What a joy to use. After some practice on some junk fabric, here is my first attempt.

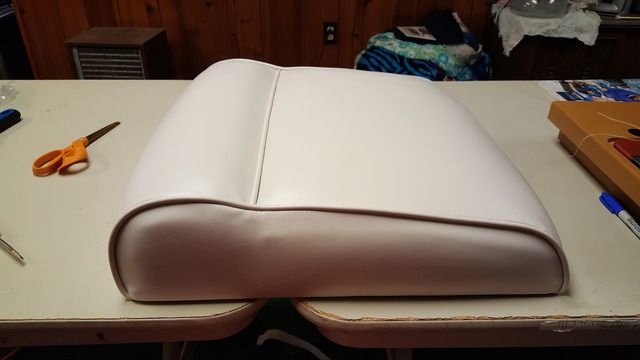

My second cushion. Came out ok but I still need practice.

I will keep updating with pics if anyone is interested. I am proud of how they have come out so far. If I can do this, anyone can.

Started out with a 1950's Viking sewing machine, which did the job ok but struggled. Going through 5 layers of vinyl was going to kill it. I borrowed a family members sailrite portable walking foot sewing machine. What a joy to use. After some practice on some junk fabric, here is my first attempt.

My second cushion. Came out ok but I still need practice.

I will keep updating with pics if anyone is interested. I am proud of how they have come out so far. If I can do this, anyone can.

Last edited: