Hello,

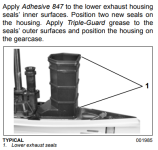

I have owned Evinrude 55 1978 since 2013 and it's been working well. Now I first time decided to change the water pump impeller and after removing the gearcase I found that a lot of exhaust gases must have been leaked inside there (black soot). In the figure (arrow) it can be seen a leak even out from gearcase. I think it must be the exhaust tube seal, but I'd like to ask if someone has any experience of this. Another question concerns a small fracture reaching the threads of the oil hole (former owner obviously hit the rock?). There has been a small oil leak, but despite of that oil has remained fairly clear. Most likely there is nothing to do with this?

I have owned Evinrude 55 1978 since 2013 and it's been working well. Now I first time decided to change the water pump impeller and after removing the gearcase I found that a lot of exhaust gases must have been leaked inside there (black soot). In the figure (arrow) it can be seen a leak even out from gearcase. I think it must be the exhaust tube seal, but I'd like to ask if someone has any experience of this. Another question concerns a small fracture reaching the threads of the oil hole (former owner obviously hit the rock?). There has been a small oil leak, but despite of that oil has remained fairly clear. Most likely there is nothing to do with this?

![20241111_203753[1].jpg](/data/attachments/403/403423-39e20919b301ff5568990a00c65d82bd.jpg)

![20241111_203647[1].jpg](/data/attachments/403/403424-bf024cded00fa8022faed183967c1a2b.jpg)