GT1000000

Rear Admiral

- Joined

- Jul 13, 2011

- Messages

- 4,916

Alrighty then, my brain is on overload and feeling quite frazzled!

I have spent the last few days looking through every post related to installing a temperature sending unit/ temperature gauge in a Merc.

I have found an untold wealth of knowledge, but nothing directly related to my current needs.

I have also been through several dozen pages of YouTube videos related to Mercury outboards and I still haven't found exactly what I am looking for.

I have perused several other Mercury Outboard related sites and got zip, zilch, nada, nothing, bingo...

I am hoping that someone in the Iboats Universe has done this project and can point me in the right direction.

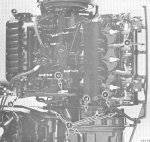

The Project: Install a temperature sending unit in the port cylinder head of a 1989, 200 HP, V-6 Mercury Outboard.

Engine Serial # 5875380

What I already know...

1- Unless I have a spare wire in the engine harness that leads to the helm, I will have to run a new wire...got that! Check!

2- I am aware that there are kits available for doing this, but it is too late, already purchased a temp gauge and a sending unit, separately, so I have NO kit to speak of...

3-I have read and seen where it is possible to install the sending unit using a Z bracket and having the sensor just making contact with the top of the cylinder head...I am not too keen on this method, as I would rather have the sensor/sending unit in direct contact with the raw water that is circulating in the engine for a more accurate reading.

However, if this is the recommended way by the experts, then that is how it will get done...

4- The engine is equipped with thermostat(s)...I am not certain if one or two and I would prefer not to open up the housings unless absolutely necessary...

5- The engine currently does not have a tell tale hooked up, but I will be installing a tee for one...which, if any of you is taking the time to read through all of this and would like to offer an opinion as to the best place to install the tee, I would really appreciate it...

6- Just in case, the temp gauge is a Faria unit that reads from 100?-250?, it requires a sending unit that reads 450Ω @ 100? and 33Ω @ 250?, the sending unit purchased from Iboats.com sends 450Ω @ 100? and 46Ω @ 220?...close enough for gubmint werk...

8-The engine is equipped with a High Temp alarm, but I feel that by the time it goes off, it might be too late...

9-I am also aware that a water pressure gauge is good to have, but that will have to wait till more funds are available...this is a project I am doing for one of my co-workers and we have what we have for now, so skip the advice on the installation of one, thank you...:watermelon:

What I need to know to accomplish this project...

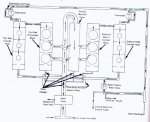

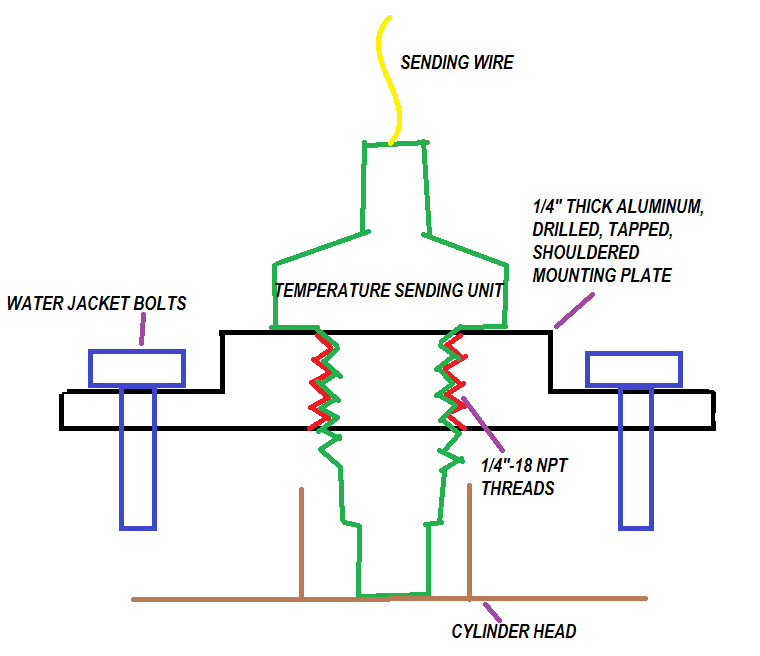

1-What is the correct spot on the port water jacket cover to drill and tap for the installation of the sending unit? There is no spot on the cover that is clearly marked that would indicate the correct placement of the ending unit.

I would like to avoid, if possible, the removal of the cover, but I would like to be certain that where I drill, is not going to harm the engine in any way, obviously.

2-Are the few shavings of the drilling that fall into water jacket of any consequence? Or will they just flush out...

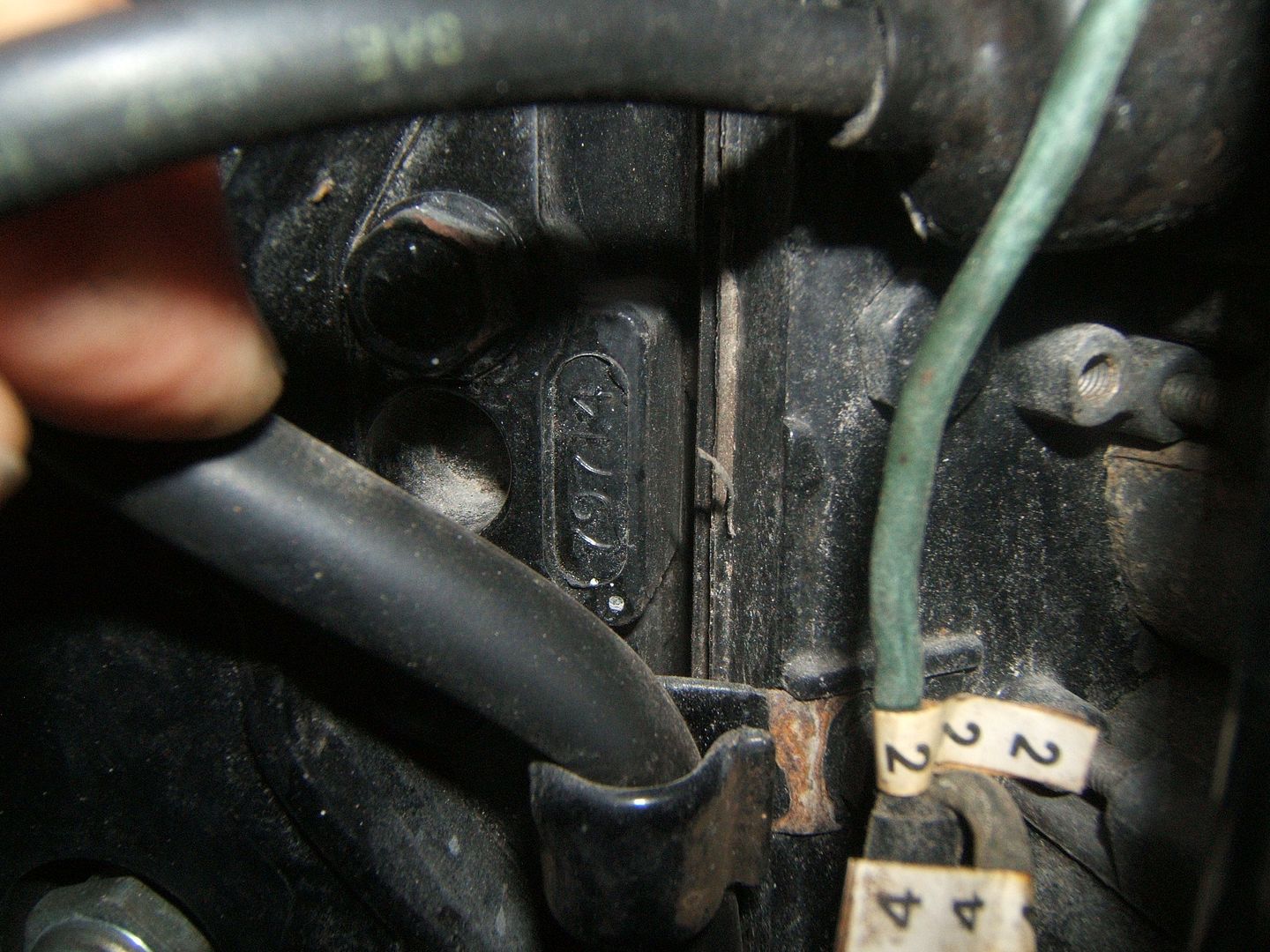

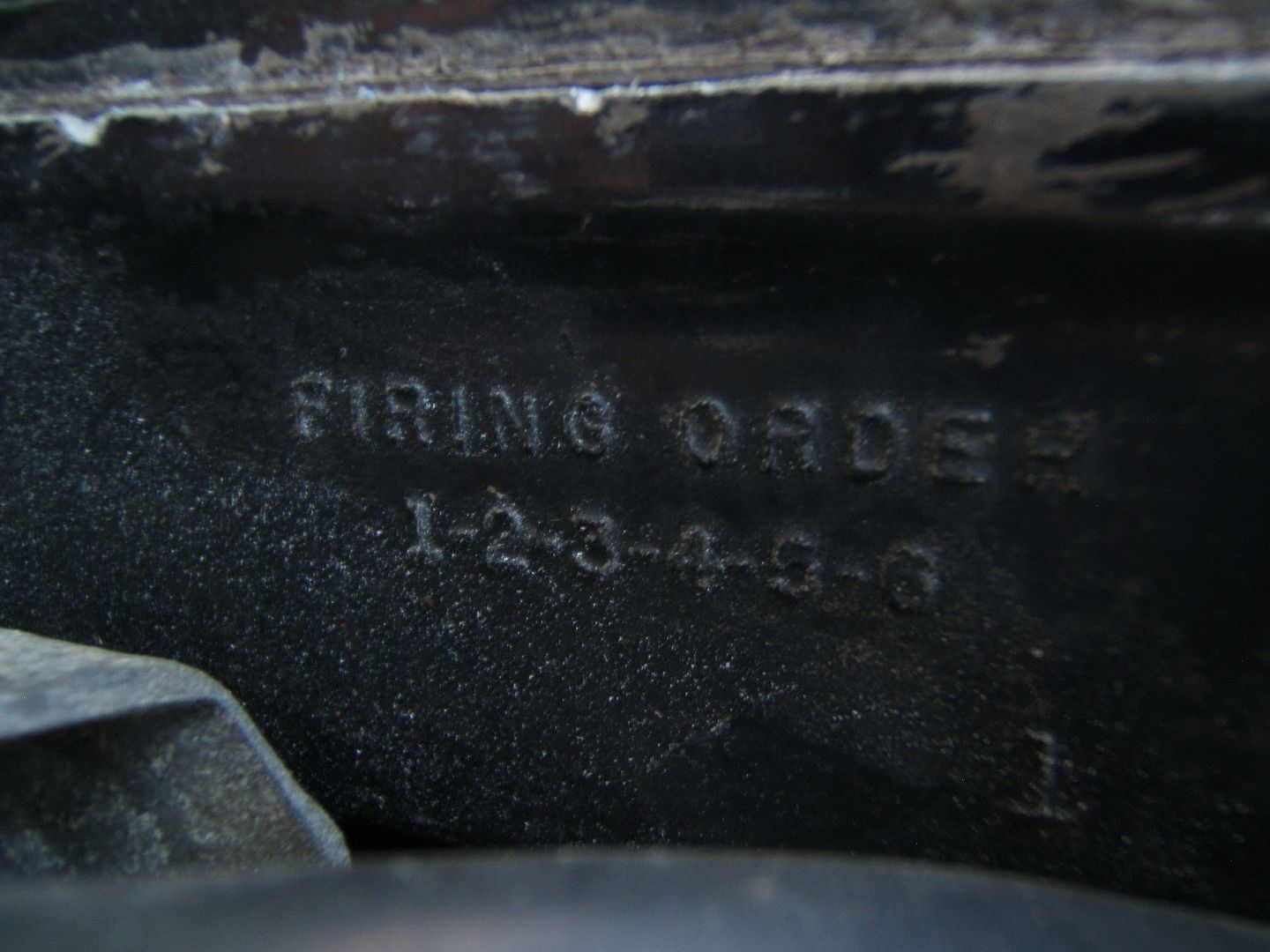

Here is a pic of the port cylinder head...It shows a recees between cylinders 1 & 2...on the starboard head, this is where the Hi-Temp Alarm Switch is installed...

Thank you all in advance for taking the time to read and offer any suitable advice.

Happy Thanksgiving!,

GT1M

I have spent the last few days looking through every post related to installing a temperature sending unit/ temperature gauge in a Merc.

I have found an untold wealth of knowledge, but nothing directly related to my current needs.

I have also been through several dozen pages of YouTube videos related to Mercury outboards and I still haven't found exactly what I am looking for.

I have perused several other Mercury Outboard related sites and got zip, zilch, nada, nothing, bingo...

I am hoping that someone in the Iboats Universe has done this project and can point me in the right direction.

The Project: Install a temperature sending unit in the port cylinder head of a 1989, 200 HP, V-6 Mercury Outboard.

Engine Serial # 5875380

What I already know...

1- Unless I have a spare wire in the engine harness that leads to the helm, I will have to run a new wire...got that! Check!

2- I am aware that there are kits available for doing this, but it is too late, already purchased a temp gauge and a sending unit, separately, so I have NO kit to speak of...

3-I have read and seen where it is possible to install the sending unit using a Z bracket and having the sensor just making contact with the top of the cylinder head...I am not too keen on this method, as I would rather have the sensor/sending unit in direct contact with the raw water that is circulating in the engine for a more accurate reading.

However, if this is the recommended way by the experts, then that is how it will get done...

4- The engine is equipped with thermostat(s)...I am not certain if one or two and I would prefer not to open up the housings unless absolutely necessary...

5- The engine currently does not have a tell tale hooked up, but I will be installing a tee for one...which, if any of you is taking the time to read through all of this and would like to offer an opinion as to the best place to install the tee, I would really appreciate it...

6- Just in case, the temp gauge is a Faria unit that reads from 100?-250?, it requires a sending unit that reads 450Ω @ 100? and 33Ω @ 250?, the sending unit purchased from Iboats.com sends 450Ω @ 100? and 46Ω @ 220?...close enough for gubmint werk...

8-The engine is equipped with a High Temp alarm, but I feel that by the time it goes off, it might be too late...

9-I am also aware that a water pressure gauge is good to have, but that will have to wait till more funds are available...this is a project I am doing for one of my co-workers and we have what we have for now, so skip the advice on the installation of one, thank you...:watermelon:

What I need to know to accomplish this project...

1-What is the correct spot on the port water jacket cover to drill and tap for the installation of the sending unit? There is no spot on the cover that is clearly marked that would indicate the correct placement of the ending unit.

I would like to avoid, if possible, the removal of the cover, but I would like to be certain that where I drill, is not going to harm the engine in any way, obviously.

2-Are the few shavings of the drilling that fall into water jacket of any consequence? Or will they just flush out...

Here is a pic of the port cylinder head...It shows a recees between cylinders 1 & 2...on the starboard head, this is where the Hi-Temp Alarm Switch is installed...

Thank you all in advance for taking the time to read and offer any suitable advice.

Happy Thanksgiving!,

GT1M