TripleJGraffis

Chief Petty Officer

- Joined

- Jan 18, 2024

- Messages

- 429

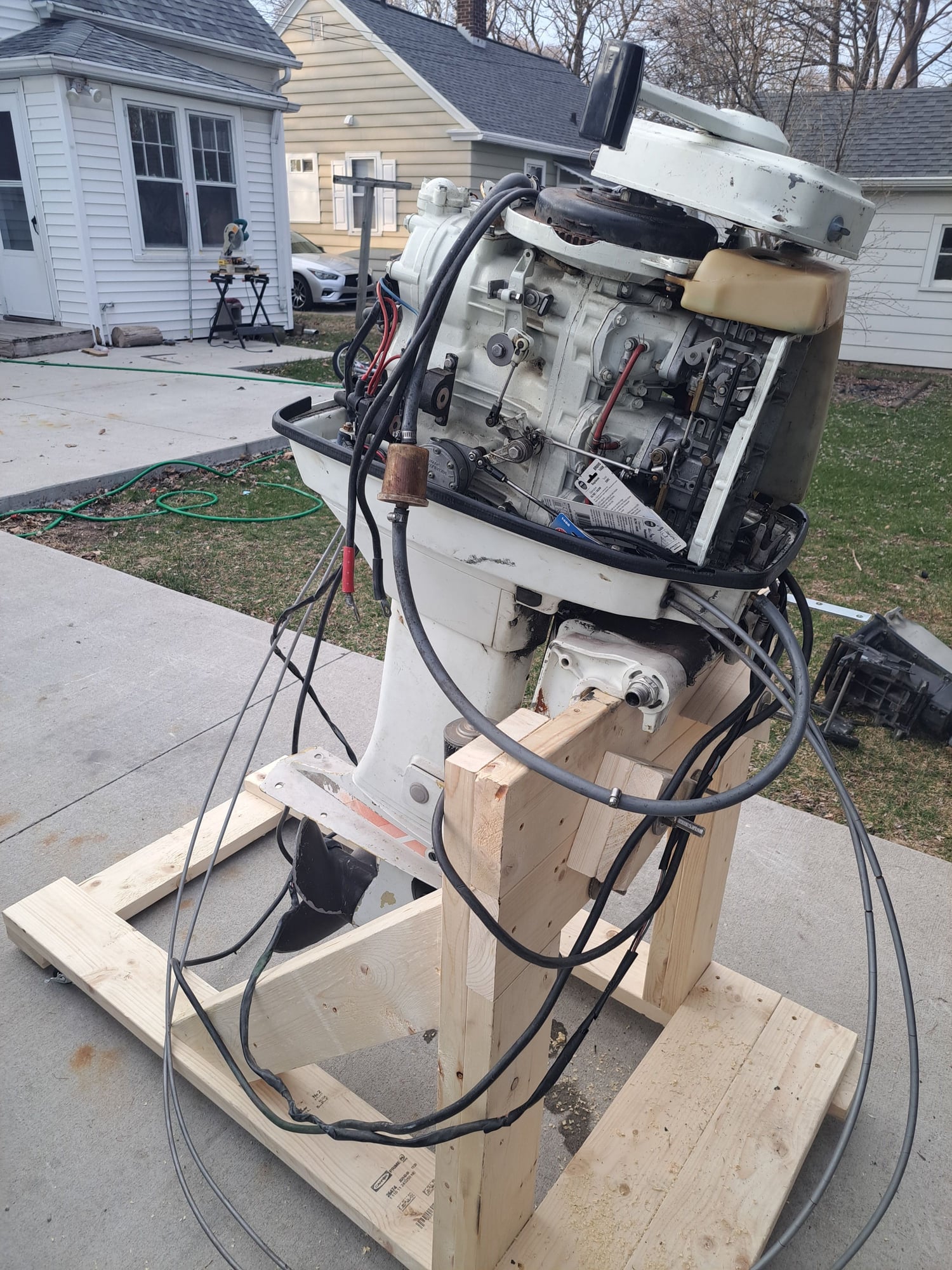

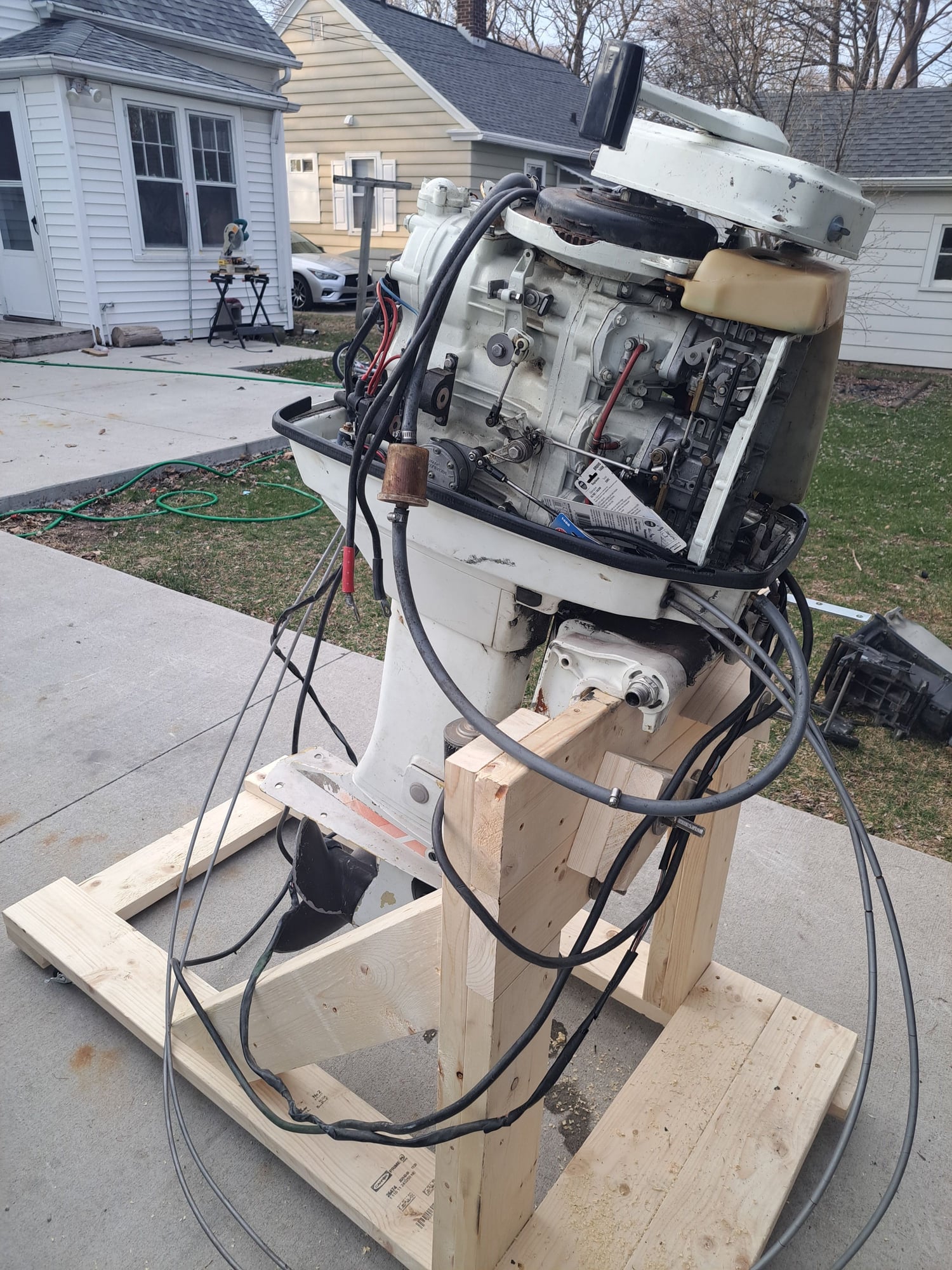

I struggled to find a decent tutorial online for an outboard stand that fit my engine. In an effort tp help others out, I am creating my own tutorial so perhaps you can easily create one of your own. This all costed me about 100 dollars at Home, but I got a new sturdy stand out of it. This is how I built mine. You can put your own twist on it to adjust to your own needs if necessary.

Happy building!!!

Materials:

Six 2x6x8's

6 casters with around 100lbs rating each

(2 swivel with brakes to attach at one end, 2 swivel without brakes to attach in the middle, 2 non swiveling to attach at the other end?

a box of no less than 60 2.5 inch deck screws

24 1.5 inch screws for the casters

1 decent sized L bracket to lock the steering arm in place

directly behind one of the 30 inch end pieces to create a 12x30 inch platform for your gas can and battery

1. Cut 2 60 inch pieces. These will be your 2 length pieces for the base

2. Cut 5 30 inch pieces. Use 2 of these for your width pieces for the base. Screw all pieces together. If wanted, add another 30 inch piece

3. Flip upside down and attach the 6 casters with the 1.5 inch screws.

4. Cut 2 33inch pieces to create the arms.

5. Attach 2 30 inch pieces to the top of both arms. This will be where you mount the outboard.

6. Cut 2 21 inch pieces and attach them to the front of the 33 inch arm pieces under the 2 30 inch cross pieces. You will now have 4x6 arm atached to a 12x30 mounting plate.

7. Attach arms at 90 degree angle to the base, touching the rear end of the 12x30 base platform.

8. You should have enough wood left over to cut 4 30-48 inch pieces. Make them all the same length and as long as they all can equally possibly be. Screw 2 togther to create 2 4x6 pieces.

9. Saw 45 degree angles into the 4 ends and make sure all pieces are the same length. These are your support braces. Attach them to upper arms and to the base.

10. Mount your motor carefully as centered as posible.

11. attach the L bracket to the end of the steering arm. ( you may need to drill into one of the holes to make it slightly larger to fit the threads through.

for your holes

12. Position the motor as straight as possible, position steering arm to either end of the mounting plate until the bracket touches the plate. Screw in place.

13. Drill your mounting holes into the mounting plate using the mounting brackets on the motor as a template Use the bolts and washers from the boat to mount the motor to the stand

You're done! Easy peasy!

I hope this helps someone!

Happy building!!!

Materials:

Six 2x6x8's

6 casters with around 100lbs rating each

(2 swivel with brakes to attach at one end, 2 swivel without brakes to attach in the middle, 2 non swiveling to attach at the other end?

a box of no less than 60 2.5 inch deck screws

24 1.5 inch screws for the casters

1 decent sized L bracket to lock the steering arm in place

directly behind one of the 30 inch end pieces to create a 12x30 inch platform for your gas can and battery

1. Cut 2 60 inch pieces. These will be your 2 length pieces for the base

2. Cut 5 30 inch pieces. Use 2 of these for your width pieces for the base. Screw all pieces together. If wanted, add another 30 inch piece

3. Flip upside down and attach the 6 casters with the 1.5 inch screws.

4. Cut 2 33inch pieces to create the arms.

5. Attach 2 30 inch pieces to the top of both arms. This will be where you mount the outboard.

6. Cut 2 21 inch pieces and attach them to the front of the 33 inch arm pieces under the 2 30 inch cross pieces. You will now have 4x6 arm atached to a 12x30 mounting plate.

7. Attach arms at 90 degree angle to the base, touching the rear end of the 12x30 base platform.

8. You should have enough wood left over to cut 4 30-48 inch pieces. Make them all the same length and as long as they all can equally possibly be. Screw 2 togther to create 2 4x6 pieces.

9. Saw 45 degree angles into the 4 ends and make sure all pieces are the same length. These are your support braces. Attach them to upper arms and to the base.

10. Mount your motor carefully as centered as posible.

11. attach the L bracket to the end of the steering arm. ( you may need to drill into one of the holes to make it slightly larger to fit the threads through.

for your holes

12. Position the motor as straight as possible, position steering arm to either end of the mounting plate until the bracket touches the plate. Screw in place.

13. Drill your mounting holes into the mounting plate using the mounting brackets on the motor as a template Use the bolts and washers from the boat to mount the motor to the stand

You're done! Easy peasy!

I hope this helps someone!