Reference thread [http://forums.iboats.com/mercruiser-i-o-inboard-engines-outdrives/5-7-vortec-2bbl-350-mag-mpi-conversion-633726.html]

I purchased a 5.7 LongBlock from a mass rebuilder and got a lot less than what I paid for. Long story short (can read my chronicles above), I'm going to build one correctly.

Engine will be a 350 MAG MPI 300HP behind a Alpha 1 Gen 2 sterndrive.

Now about me: I can read manuals, I can use precision tools I have technical skills (more related to helicopters and turbine engines) I suck with English and writing cursive! I only know bad English and improper punctuation.

With that said I'm in no way an automotive/marine guy. This engine is a project for a 1999 21ft SeaRay 210 Sundeck - father/son restore-RePower project. I want cheapest pump gas ability when complete.

So, questions :

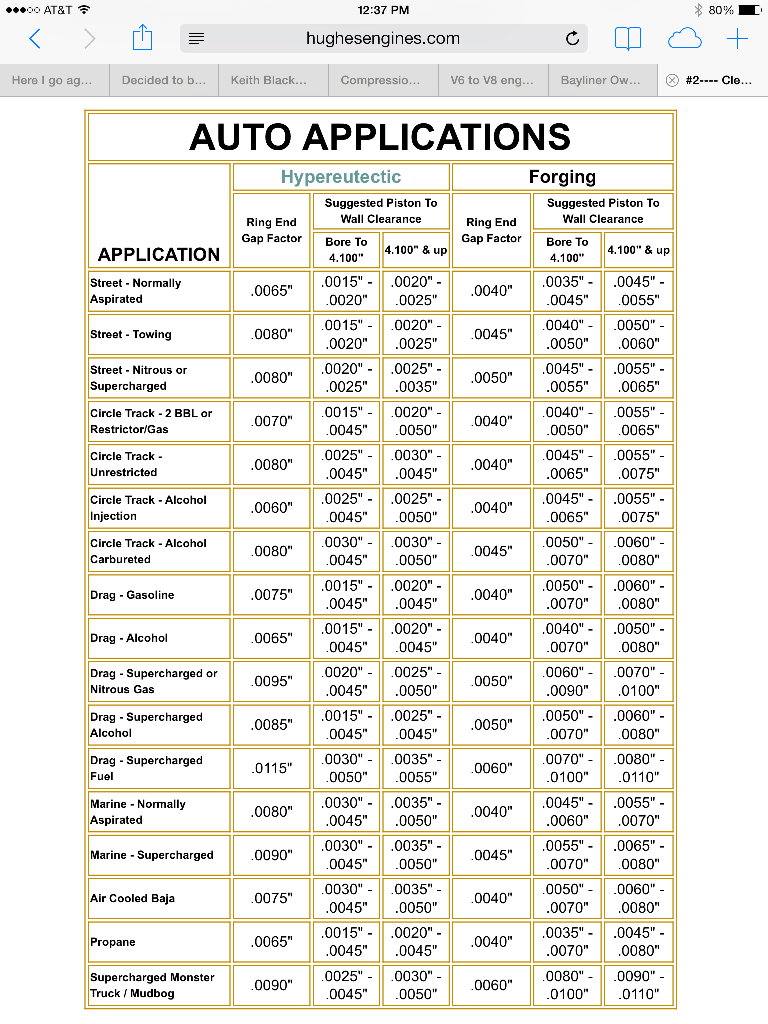

Bondo pointed me to link about Vortec squish and how it's a bad idea to use flattop pistons because of no squish area provided. I'm sold! So I'm trying to get my head around this. In the referenced link above my last few posts carry on my questions.

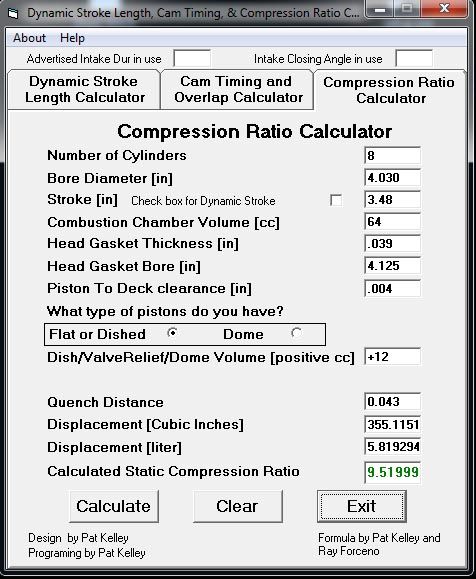

What is the proper procedure to obtain the .043 squish area? I understanding decking, milling and mockup.

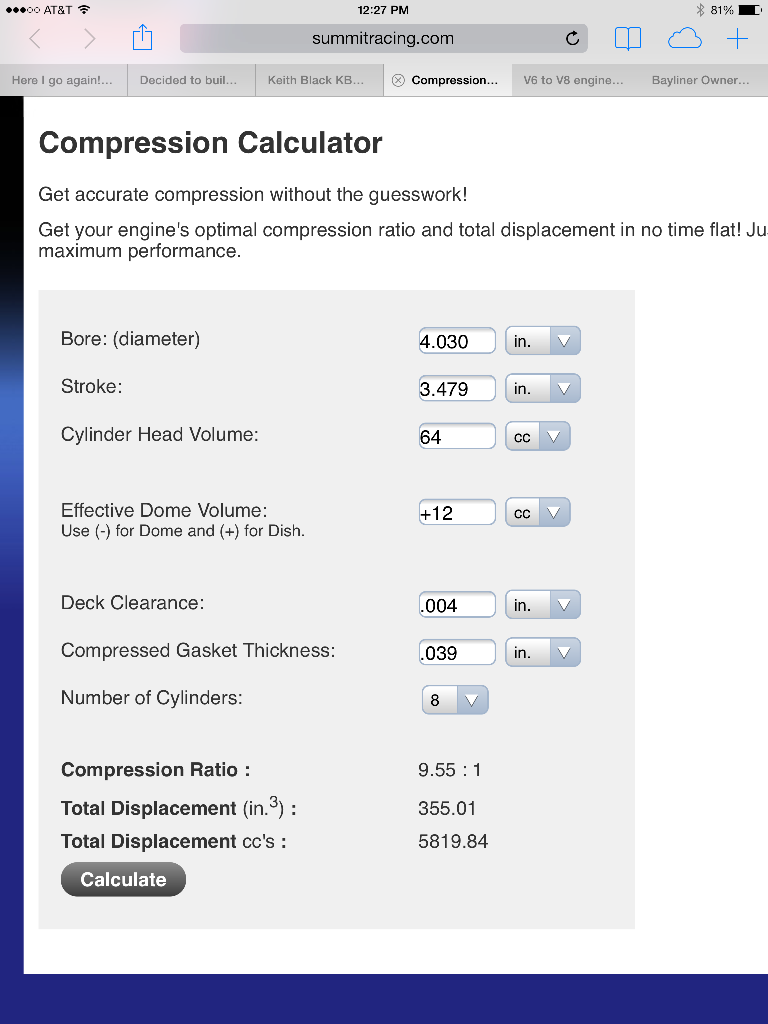

I'm thinking of going with D-Dish style pistons (cast or hyper), but I have to get my pistons .004 in the hole. My head gasket is .039 compressed. Do the pistons need to be a certain depth to account for the increased compression (basically the depth of the D milled in the piston)?

I don't want to change piston rods, so only two ways to get there I'm thinking. Lower piston wrist pin location or almost zero decking my block. If I zero deck I'm thinking I have to mill my intake to match. However I don't know if you can buy pistons with different wrist pin locations, or if I'm making this too difficult

Thanks for any replies and suggestions. Please keep in mind I'm a newbie with enough experience to be dangerous!:lol:

I purchased a 5.7 LongBlock from a mass rebuilder and got a lot less than what I paid for. Long story short (can read my chronicles above), I'm going to build one correctly.

Engine will be a 350 MAG MPI 300HP behind a Alpha 1 Gen 2 sterndrive.

Now about me: I can read manuals, I can use precision tools I have technical skills (more related to helicopters and turbine engines) I suck with English and writing cursive! I only know bad English and improper punctuation.

With that said I'm in no way an automotive/marine guy. This engine is a project for a 1999 21ft SeaRay 210 Sundeck - father/son restore-RePower project. I want cheapest pump gas ability when complete.

So, questions :

Bondo pointed me to link about Vortec squish and how it's a bad idea to use flattop pistons because of no squish area provided. I'm sold! So I'm trying to get my head around this. In the referenced link above my last few posts carry on my questions.

What is the proper procedure to obtain the .043 squish area? I understanding decking, milling and mockup.

I'm thinking of going with D-Dish style pistons (cast or hyper), but I have to get my pistons .004 in the hole. My head gasket is .039 compressed. Do the pistons need to be a certain depth to account for the increased compression (basically the depth of the D milled in the piston)?

I don't want to change piston rods, so only two ways to get there I'm thinking. Lower piston wrist pin location or almost zero decking my block. If I zero deck I'm thinking I have to mill my intake to match. However I don't know if you can buy pistons with different wrist pin locations, or if I'm making this too difficult

Thanks for any replies and suggestions. Please keep in mind I'm a newbie with enough experience to be dangerous!:lol: