No distractions or hijacks will be tolerated, oooh look shiny stuff

. Seriously though, I don't mind at all, this is how we all learn from each other and our experiences we have and that is what makes this site so great. Any information or thoughts and ideas are welcome here, and joking around is all in good spirits, have fun today because we may not be together tomorrow.

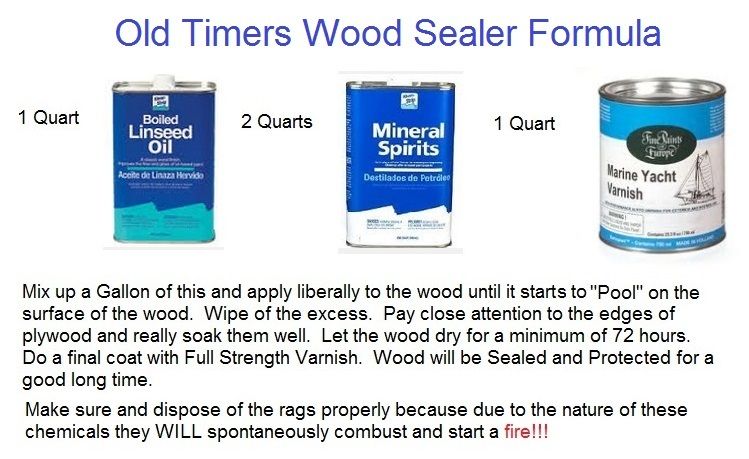

Thanks for bringing up the deck Decker83, I also was planning to do the deck sort of the same. My idea is OTF both top and bottom and the edges, Spar Urethane the same and then carpet on top. I am uncertain of what is the best way to get the carpet to stick. Paint the deck first, just carpet glue, snap in? What are your thoughts? I know Watermann is a huge fan of the carpet (just kidding Watermann, I did read the V5 thread, absolutely beautiful job by the way) and I already have the carpet, chosen by the Admiral of course.

I have read many tin restoration threads and have trouble finding information or pictures when I am looking back to remind myself what someone else did. I am thankful for all the reading material you all have provided, Watermann, BWR, RickAirmedic, cheapboatKev, ratherbboating, jasoutside(still reading) just to name the ones I can remember. Thanks to all and then some.

Time to get back to work on the tinny, I will post pictures if I can make some progress.