Sea Rider

Supreme Mariner

- Joined

- Sep 20, 2008

- Messages

- 12,345

Is the ring locating pin for the broken ring still in the piston?

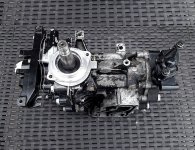

The piston's ring locating pin sits in place. It's impossible for a ring to break while running, never have seen such scenario in more than 13 years working with Tohatsu motors. Can seize a piston and piston ring ring but not break it due to poor lubrication, forgot to add oil to the fuel which will enevitably screw the entire motor to Kaputland.

OTOH, the motor will recover from an extreme overheat due to a bad thermostat or an impeller failure specially when the lower legs has collected seaweed, plastic bags even a banana peel once it has cooled down completely. Been there 3 times so to speak with reason.

The motor it's severely damaged already, why cry over spilled milk trying to find a culprit, the entire powerhead needs a semi overhaull. Tomarrow will know the cost of the machine shop work to install 2 new cylinder sleeves and bore them to match the new piston's diameter...

Happy Boating

OTOH, the motor will recover from an extreme overheat due to a bad thermostat or an impeller failure specially when the lower legs has collected seaweed, plastic bags even a banana peel once it has cooled down completely. Been there 3 times so to speak with reason.

The motor it's severely damaged already, why cry over spilled milk trying to find a culprit, the entire powerhead needs a semi overhaull. Tomarrow will know the cost of the machine shop work to install 2 new cylinder sleeves and bore them to match the new piston's diameter...

Happy Boating