I have a 1994 Glastron with a 5.7 GI Volvo Penta engine with electronic ignition, 2 barrel Holley carb with electric choke. Owned boat for about 6 weeks.

Boat worked fine the first few times I took it out, but then died when coming back to dock and would not restart.

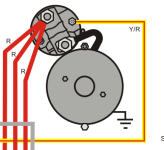

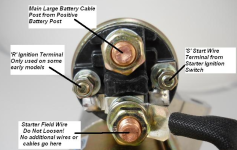

I found that the coil was not getting power when the ignition was in the run position, but the coil did received power when the key ignition was fully turned to the start position. ( My first thought was bad ballast resistor ) I got the engine running again by running a jumper wire from the starter solenoid to the positive side of the coil. See picture below.

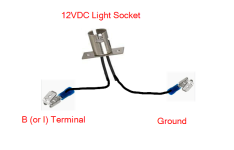

Here are my questions: The coil I have says to use an external resistor, but this boat has electronic ignition, ( meaning no points ). I thought the external resistor was only used on old point ignition system. So I'm confused on this topic.

More importantly the two questions I really have are: 1) is it safe to run a permanent wire from the starter to the positive side of the coil like I currently have the yellow jumper wire and 2) Since I'm not using an external resistor and I have electronic ignition, should I have purchase a different coil?

The coil I have right now is an SIE 18-5437 Ignition Coil

Right now everything sounds like it is running fine using the yellow jumper wire and I should just make that a permanent connection. But I am a little affraid, I just don't want to get out on the lake and find out that I fried the coil by sending it too much voltage.

You have any thoughts on this. I'm not an expert by any means and your thoughts would be greatly appreciated.

My gut feeling is the wiring in this boat has a ballast resistor or bad resistor wire that burnt out and that is why the coil wasn't getting any power. But for the life of me, I can not find any sort of resistor going to the coil.

Final note, I believe this boat originally had a 5.0 volvo penta engine in it, and somewhere along the line the engine was replaced with a 5.7. Nicely put together if that is the case.

Boat worked fine the first few times I took it out, but then died when coming back to dock and would not restart.

I found that the coil was not getting power when the ignition was in the run position, but the coil did received power when the key ignition was fully turned to the start position. ( My first thought was bad ballast resistor ) I got the engine running again by running a jumper wire from the starter solenoid to the positive side of the coil. See picture below.

Here are my questions: The coil I have says to use an external resistor, but this boat has electronic ignition, ( meaning no points ). I thought the external resistor was only used on old point ignition system. So I'm confused on this topic.

More importantly the two questions I really have are: 1) is it safe to run a permanent wire from the starter to the positive side of the coil like I currently have the yellow jumper wire and 2) Since I'm not using an external resistor and I have electronic ignition, should I have purchase a different coil?

The coil I have right now is an SIE 18-5437 Ignition Coil

Right now everything sounds like it is running fine using the yellow jumper wire and I should just make that a permanent connection. But I am a little affraid, I just don't want to get out on the lake and find out that I fried the coil by sending it too much voltage.

You have any thoughts on this. I'm not an expert by any means and your thoughts would be greatly appreciated.

My gut feeling is the wiring in this boat has a ballast resistor or bad resistor wire that burnt out and that is why the coil wasn't getting any power. But for the life of me, I can not find any sort of resistor going to the coil.

Final note, I believe this boat originally had a 5.0 volvo penta engine in it, and somewhere along the line the engine was replaced with a 5.7. Nicely put together if that is the case.