- Joined

- Jul 18, 2011

- Messages

- 18,915

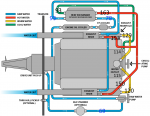

Just a thought. Pull the water inlet housing off the transom assembly on that port engine. Visually inspect the end of the water inlet hose for corrosion / blockage. I only have 1 engine, but I just fixed this on my boat. I'm not sure what you used to snake that hole, but since you DID manage to change the symptom when you did it, I suspect that you managed to disturb a blockage just enough to get a bit more water flow than it had before. If you remove the pivot pins from the bell housing and remove the U joint bellows from the bell housing, you will have enough access to change it. Merc has a "Design 2" hose with a plastic tube where it goes through the transom that is very easy to install.

Thanks for the input. I may try to snake the inlet tube again. My challenge is that the boat, being a 33 footer, is a bit costly ($660) to take out of the water and re-launch. So, most of my 'in-season' maintenance is done with the boat in the water. I had the outdrive off over the winter and I don't recall seeing any marine life in the outdrive water duct or inlet tube at the bell housing. However, it is possible that a barnacle grew inside the outdrive water inlets and is now dislodged and working its way up the inlet tube as the sea water pump tries to suck in water.