HT32BSX115

Supreme Mariner

- Joined

- Dec 8, 2005

- Messages

- 10,083

You might be able to find thicker gasket material....(I assume you're using sealant?)

This is to say that both engines are now running at nearly the same temp with the "same" stats? Problem solved?OK, all set with the Starboard engine t-stat installation.

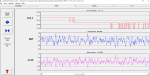

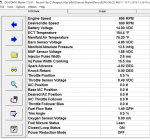

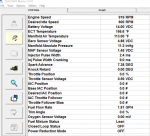

I ran the starboard engine up to temperature with the new t-stat (w/ 2 small by-pass holes). the engine settles in at about 168 per the gauge at idle speeds and no load.

So that is the same as the port engine. We are 'apples-to-apples' at this point.

This is to say that both engines are now running at nearly the same temp with the "same" stats? Problem solved?

Hmm..........................

Essentially, are the engines cooling differently because of the thermostats? perhaps, so making them essentially the same remedies that question.....................................

Probably can do the IR Temp readings again and the sea water flow testing.

Ideally, I'd like to get the temp gauges at the helm to be more consistent with the ECM temp readings, but I'm not sure there is a good way to do that. The fact that they are reading 10 degrees higher puts a bit of fear factor into the boat operation.

The following link won't work here at iboats but search online "Troubleshooting Teleflex Water Temperature Gauges :Water Temperature System Accuracy?".Oh, I just had a thought about the ECT temperature reading from the MEFI data vs. the helm gauge. VDO gauges use the Eropean sender standards for resistance and I'll bet the temp sender is the U.S. Standard, since it needs to be compatible with the MEFI.

Just not sure the exact ohm ranges of the U.S. Vs Euro for the temperature senders. I'll see what I can Google.

My sender has 2 wires,

If you have "visibly" less raw water flow, your risers should of course be hotter and you may be at (or past) the limit of the excess heat exchanger transfer capability.the water exiting the outdrive was visibly less in volume than the starboard engine and was quite hot (steaming). So, I think my issues lies within the outdrive, intake hose, fitting or sea water strainer.

/////////////

Anyway, I have a good idea of where the port engine problem lies.

If you have "visibly" less raw water flow, your risers should of course be hotter and you may be at (or past) the limit of the excess heat exchanger transfer capability.

This may be the "smoking gun" all along....

"Fingers Crossed"!!

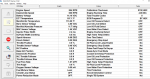

Port

1=129

3=126

5=118

7=128

2=136

4=125

6=132

8=134

Starboard

1=125

3=123

5=118

7=120

2=125

4=121

6=124

8=127