I will be changing the U-Joint on my OMC Cobra Outdrive. Water got into the OD and rusted the U-Joint and the bearing. (See Figure "Rusted UJoint")

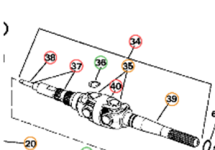

I will either take the OD to a shop and have them replace the U-Joint and perhaps overhaul the OD OR Buy the U-Joint assy and install it myself. (See UJoint1)

Any thoughts on that? Have any of you done that yourself?

It appears that the first thing to do after removing the OD is to remove the Bearing Carrier #28.

(See Figure BearingCarrier)

I have removed the 4 Allen bolts #41 but the carrier has not come loose.

Any suggestions?

I also see that there are different thickness shims #30. That tells me that there are some detailed measurements to take to know what shim to use. That may be beyond my ability.

Any more thoughts?

I will either take the OD to a shop and have them replace the U-Joint and perhaps overhaul the OD OR Buy the U-Joint assy and install it myself. (See UJoint1)

Any thoughts on that? Have any of you done that yourself?

It appears that the first thing to do after removing the OD is to remove the Bearing Carrier #28.

(See Figure BearingCarrier)

I have removed the 4 Allen bolts #41 but the carrier has not come loose.

Any suggestions?

I also see that there are different thickness shims #30. That tells me that there are some detailed measurements to take to know what shim to use. That may be beyond my ability.

Any more thoughts?