AKJohne

Petty Officer 1st Class

- Joined

- Mar 26, 2017

- Messages

- 220

0K158784 Alpha I ~ 570 hours on rebuild (not by me)

Saturday we were wrapping up a week long trip and had good weather, running From Unakwik to Naked Island, about 25 miles, we had good water and was running hard, ~ 3800-3950 RPMS. Typically run 3200 to 3600 sometimes 3800, have recently seen 4800+ with the current prop. In any case I noticed rpm and speed dropping slightly, initially I thought the tension screw on the binnacle maybe needed tightening, although it had never backed off before. Then noticed the temps were up over 180, maybe 195 area. Typically runs just above 160, about 170. ALWAYS... I scan the gauges pretty often but can get complacent. I backed off immediately and pretty quickly the temps returned to normal, we were fishing so stop and drift, start, move, drift. I immediately noticed some hard staring and a miss. Pulled plugs and found this in #3 hole.

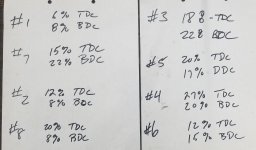

I checked comp at all 8 with digit in spark plug hole and noting on #3. These were Denso Platinum plugs and changed all 8 to the spare Delcos I had. We finished our day at more conservative RPMS and back to Valdez the following day. It was another 75 miles back to the harbor all told. Ran pretty good for a 7 cylinder, cruise along at 3200 and 22-25 mph, A uninformed passenger would not know anything was amiss. Noticeable at idle. Today I verified with a actual compression gauge and verified dead hole, the rest of the cylinders OK, one a130, some at 155, cold motor, not great but OK.

A leak down test confirmed intake issue, no air noticeable at exhaust or valve covers.

I am in the process of removing the head today but ran out of gitty up, I am hoping the piston is ok. Once the head is off I will decide if I will rebuild or replace, Vortec or original. (12 bolt manifold).

The nature of this post is the "what caused it"? My long time friend, smarter than me on engines thought the Delco plugs were a little on the light side, (I Rebuilt the weber 4V carb last year and used the original jets). He also thought the toasted plug was a serious case of detonation/preignition.

Timing was set at 12 base and should have been 10... if that was the cause then I learned a valuable lesson. Thunder bolt ignition with knock sensor, no funny alcohol fuels here, I always run 90 octane when I can, but in the harbor it is 87 only.

Any ideas here? You guys have always been helpful, I rarely contribute to this forum but always appreciate the help I receive. Thanks!

Saturday we were wrapping up a week long trip and had good weather, running From Unakwik to Naked Island, about 25 miles, we had good water and was running hard, ~ 3800-3950 RPMS. Typically run 3200 to 3600 sometimes 3800, have recently seen 4800+ with the current prop. In any case I noticed rpm and speed dropping slightly, initially I thought the tension screw on the binnacle maybe needed tightening, although it had never backed off before. Then noticed the temps were up over 180, maybe 195 area. Typically runs just above 160, about 170. ALWAYS... I scan the gauges pretty often but can get complacent. I backed off immediately and pretty quickly the temps returned to normal, we were fishing so stop and drift, start, move, drift. I immediately noticed some hard staring and a miss. Pulled plugs and found this in #3 hole.

I checked comp at all 8 with digit in spark plug hole and noting on #3. These were Denso Platinum plugs and changed all 8 to the spare Delcos I had. We finished our day at more conservative RPMS and back to Valdez the following day. It was another 75 miles back to the harbor all told. Ran pretty good for a 7 cylinder, cruise along at 3200 and 22-25 mph, A uninformed passenger would not know anything was amiss. Noticeable at idle. Today I verified with a actual compression gauge and verified dead hole, the rest of the cylinders OK, one a130, some at 155, cold motor, not great but OK.

A leak down test confirmed intake issue, no air noticeable at exhaust or valve covers.

I am in the process of removing the head today but ran out of gitty up, I am hoping the piston is ok. Once the head is off I will decide if I will rebuild or replace, Vortec or original. (12 bolt manifold).

The nature of this post is the "what caused it"? My long time friend, smarter than me on engines thought the Delco plugs were a little on the light side, (I Rebuilt the weber 4V carb last year and used the original jets). He also thought the toasted plug was a serious case of detonation/preignition.

Timing was set at 12 base and should have been 10... if that was the cause then I learned a valuable lesson. Thunder bolt ignition with knock sensor, no funny alcohol fuels here, I always run 90 octane when I can, but in the harbor it is 87 only.

Any ideas here? You guys have always been helpful, I rarely contribute to this forum but always appreciate the help I receive. Thanks!