Yeah transom work seems daunting, having to pull the motor and all but it's really not bad with an OB. You didn't post up the year of your boat but I would recommend doing the extra work and replacing the transom and here's why.

If it's original then I know plywood and original boat builders apparent aversion to properly sealing the ply in the transoms. If pulled, you'll find also there's galvanic corrosion getting a foothold on the transom skin looking like white powder. If the ply isn't properly sealed it can be dry right now but from the years of use *wet and drying) the ply starts to de-laminate.

Peace of mind is knowing that boat is solid from one to the other and doesn't just "seem solid."

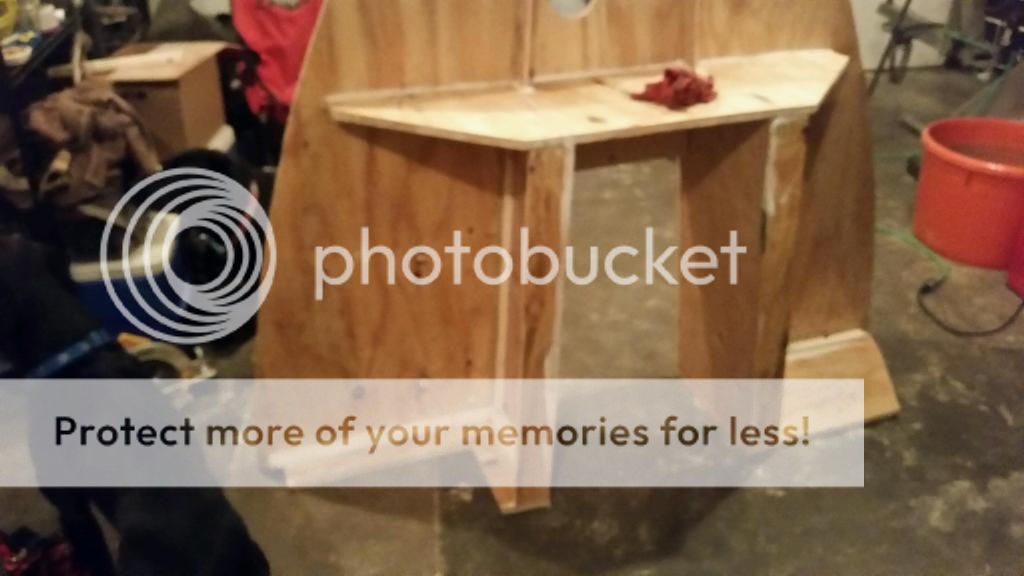

It is a 1989. Ugh I know I know. you have convinced me to investigate further into the transom. I have had to replace some screws that held the Splashwell and the screws snugged up nicely I do not notice any flex in the transom. The boat has always been strictly freshwater and always trailered. The floor that was actually in fair condition and the rest of the wood was damaged from being left in the rain and sun, uncovered. it spent the last 10 years of its life parked in the back of a Quonset after having some of the carpet redone and consoles recovered.

Yes I am just trying to convince myself I do no need to get into the transom