danielvanalphen

Seaman

- Joined

- Aug 9, 2021

- Messages

- 58

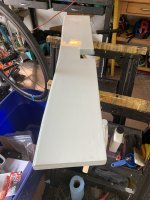

I'm remaking the transom of my 13ft alluminium boat and have 18mm marine grade plywood that I'm going to use, I'm just wondering what is the best sealer to coat the plywood in, in order to make it as waterproof as possible, thanks