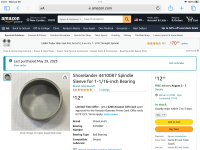

I've got a trailer axle that has slight damage , mainly some grooves, on the grease seal face. 11/16 " axle. ordered a repair sleeve that fits perfectly and doesn't wiggle, but doesn't press fit on like it should...

I thought maybe using jb weld as a glue to stick the sleeve on.....

should/would that work?

I thought maybe using jb weld as a glue to stick the sleeve on.....

should/would that work?