rustybronco

Petty Officer 2nd Class

- Joined

- Oct 24, 2021

- Messages

- 134

Around $91 for that bearing kit on Ebay. PM if you want the item number. GLM part numberTimken bearings.Nope, the ujoints were fine. It's the drive shaft bearings that were bad.

Around $91 for that bearing kit on Ebay. PM if you want the item number. GLM part numberTimken bearings.Nope, the ujoints were fine. It's the drive shaft bearings that were bad.

Would replace the ring it beat up, make sure the big square ring is properly glued in there. ive had a couple times where alignment is not text book perfect aka two fingers on bar, but drive goes in perfectly.So I had the shop rebuild the top end after all due to time constraints and now I'm having issues getting the drive back in.

I've spent about 10 hours trying to get the alignment right but the closest I can get it still requires 3 or 4 fingers to get the tool in and out. Not nearly as easy as some of the videos I've seen where you can grab it with 2 fingers and it slides around like nothing. But when I go to put the drive in, it'll go as far as the coupler and no further. I can feel the splines trying to mate when I turn the prop but for the life of me It just won't go in any further. I did notice that the drive bellows retaining ring was getting a little dinged up from pulling the drive shaft and reinserting it multiple times. Is there usually any issues with the u-joint hanging up on the bellow ring preventing the drive from going any further?

The last time I pulled the drive out the ring actually popped off and looked quite mangled (I'll post a pic shortly).

Anyway, I assume it's still an alignment issue that's my problem but you'd think that being this close I could still force it in a bit couldn't I?

Yeah, the splines in the coupler look good and there is a decent amount of grease in there but not enough to restrict anything. I can see the far end of the coupler no problem. I can't get the drive shaft any further in to the coupler for the grease to be an issue anyway. The drive splines are just barely contacting the coupler splines but not sliding in any further. Everything is in FWD. I can feel the splines trying to mesh when I turn the prop.Would replace the ring it beat up, make sure the big square ring is properly glued in there. ive had a couple times where alignment is not text book perfect aka two fingers on bar, but drive goes in perfectly.

i have had it where i think there is so much grease from alignment checking when you put the drive on there is resistance from grease In coupler.

would check the coupler and drive shaft splines , verify shift shaft is in fwd both meet ok and are straight ahead.

are you keeping the drive in fwd by holding the prop counter clockwise to keep it locked in gear might be poping out of drive so turning the prop isnt turning the driveshaft

Don't know how much experience you have putting the drive back on, but I find that the key is aligning the drive to be perfectly level with the bell housing when you slide it in. The shaft can definitely flop otherwise. Turning the prop 90' so the u joints are flopping in a different direction sometimes helps.What I mean is that the tip is a little off the center line of the coupler because the thinner portion of the shaft is sitting in the gimbal bearing? The U-Joint is quite floppy and may be sagged down a bit inside the housing pointing the shaft upwards for instance?

Here's the bellows ring that fell out...

View attachment 364495View attachment 364496

Then watch my videos on gimbal bearings and installing the drive. (link at the bottom of my forum signature )Zero experience whatsoever lol. Thanks for the tip

Yeah I did that a few times already.The other thing can help is to have the gimbal bearing aligned with the coupler perfectly. Gimbal bearings 'gimbal'. Meaning they the can twist about like an eyeball. To get them aligned, I like to put the alignment bar in all the way, then take a deadblow hammer and rap the end of the alignment bar up, down, left, and right.This will get the bearing aligned to the coupler.

Yup I've watched a them few times Chris lol! Definitely helpful videos thank you.Then watch my videos on gimbal bearings and installing the drive. (link at the bottom of my forum signature )

Yeah I've seen that diagram before, just hard to get in there and get a good look at everything.

1996 4.3 LX 700hrsIf you have a left/right alignment issue, then it could be caused by an uneven transom thickness. If the alignment was correct in the past, then something (bad) has happened.

BTW, all we know so far is that the drive is an Alpha One Gen II. Any chance of letting us in on the engine and it's year?

Chris.....

1996 4.3 LX 700hrs

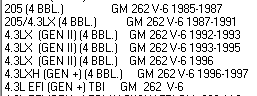

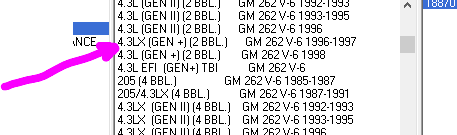

OF761554 4bbl weber carb1996 was the year when GM/Merc changed from the Gen II engines to the Gen+ (yes, as well as a Gen II drive, the V6 engines also came in Gen II. Confusing if you're new to these parts)

Having said '4.3LX', I'm thinking it's a Gen II engine with a 4bbl Weber 9600 series carb. If you want to verify that, the Gen II engines have 12 intake manifold bolts, in at 45 degrees, the Gen+ engines have 8 intake bolts in vertically (or you can post the engine serial number and we can look it up and check for you).

Chris......

View attachment 364607

EDIT: Just checked, a 1996 2 bbl Gen+ V6 was also called '4.3LX'.