Woodonglass

Supreme Mariner

- Joined

- Dec 29, 2009

- Messages

- 25,932

You can easily do what you propose with out any structural consequences.

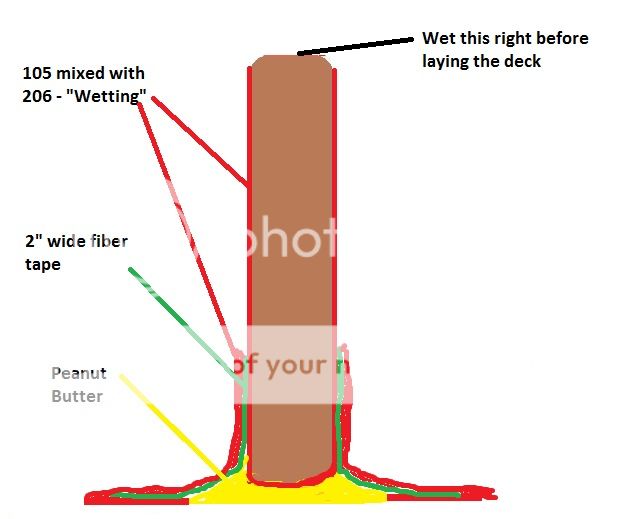

First off, it's your boat and you can do as you wish. What the sailboat guy told you is basically correct for non structural fiberglassing but NOT for stringers in a boat like yours. It would not be correct for Sailboat stringers either. The stringers are essential to provide structural strength to the hull to keep it from flexing under the pounding it receives from waves and wakes in the water. The fiberglass is what provides this strength along with the wood core. The wider the base of the stringer the better the weight distribution.

Epoxy is strong and has better waterproofing characteristics than Polyester Resin but NOT that much more. 2" tabbings is not nearly enough to provide the vertical structural strength required for your stringers. That's only 1" of cloth on the stringer and 1" on the hull. With the fillet you won't ever get out onto the hull. You will need a minimum of 3 gallons of resin to do your stingers and bulkheads and then theres the resin needed to make the PB to bed the stringers and bulkheads with. For every Quart of resin used to make PB it takes 1 1/2 quarts of Silica to thicken it. Is there a reason you decided to use epoxy instead of Polyester.