Hey Everyone,

I've been lurking around for a while now and thought it was time to post since I'm starting (and maybe ending) restoration of my 1976 Starcraft Holiday IO.

History on the boat - It belonged to my Father-in-Law and was handed over to us back in 1995 I believe. he purchased it around 1986 we think. It's always been a Lake Erie boat as far as we know as it was purchased from a local dealer.

Not sure what all was done by the dealer before my FIL purchased it, but it has been repainted at some point before then

It's been a very low maintenance boat for all those years, just taking care of the routine items, replacing part of the floor under the battery, replacing wood in the seats, rebuilding the carb, and other minor issues. It was stored outside for a few years before that and not used while my kids were young. Always done my own maintenance and repairs except for the exhaust and shift cable boots back in the late 2000's. About 4 years ago, we had an overheating issue, failed impeller, and burned up the motor. Had a local marine shop pull it and another local shop rebuild it. The gimble housing was replaced with a newer piece and the hydraulics updated inside and out. The MerCruiser 120 has been running great since. The kids tube, wakeboard, and ski though not as much as they are getting older, but we still get out, cruise and discover new areas around the lake.

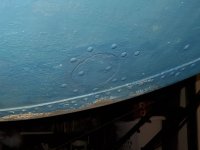

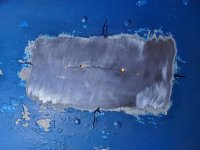

The last few years the floor has been getting soft, the seats had seen better days, some of the gauges starting to fail and the bilge pump has been running more. We've always checked for leaking rivets and nothing major, just a couple more each season. So at this point I thought it was a good time to fix the rivets, replace the floor, replace the seats, and make a few changes that I've seen on the forum. Was planning to have a local guy paint and maybe replace the leaking rivets and hopefully be back on the water in the summer. The last couple weeks I've been removing parts, documenting as I go. I pulled the floor today, the styrofoam was surprisingly clean with just a little dark staining on the bottom pieces towards the stern. As I was pulling the floor that would be under the front seats, I noticed the runner was leaned over. Removing that section of floor was when my worst fears were realized. 8 cracked ribs and broken runner on the port side. The ribs are cracked right where the runner attaches. I know 3 of the ribs were really loose as that's where most of the leaks were. I saw one patch on the inside starboard side towards the bow, must have been done before the family's ownership. I don't see any stress cracks in the skin while looking from the inside. Can't see anything from the outside as there are several coats of rubberized paint on the bottom. The strake on that side does have a crack where the front weep hole is and there are a few really loose rivets

Not sure I want to take this on myself since its structural in nature. I searched around the forum and didn't find anything on cracked ribs or repair. We've got a call out to a friend whose brother has been in the boat repair business to see if he knows anyone who could do the repair.

Fortunately, the only thing I've purchased so far was the front seats so I'm not out a lot of money yet should it be unrepairable. Obviously, the Captain has sentimental attachment so that is a huge factor.

This forum has been great over the years with helping me maintain the boat and hoping to get your perspective on if this is worth repairing.

I've been lurking around for a while now and thought it was time to post since I'm starting (and maybe ending) restoration of my 1976 Starcraft Holiday IO.

History on the boat - It belonged to my Father-in-Law and was handed over to us back in 1995 I believe. he purchased it around 1986 we think. It's always been a Lake Erie boat as far as we know as it was purchased from a local dealer.

Not sure what all was done by the dealer before my FIL purchased it, but it has been repainted at some point before then

It's been a very low maintenance boat for all those years, just taking care of the routine items, replacing part of the floor under the battery, replacing wood in the seats, rebuilding the carb, and other minor issues. It was stored outside for a few years before that and not used while my kids were young. Always done my own maintenance and repairs except for the exhaust and shift cable boots back in the late 2000's. About 4 years ago, we had an overheating issue, failed impeller, and burned up the motor. Had a local marine shop pull it and another local shop rebuild it. The gimble housing was replaced with a newer piece and the hydraulics updated inside and out. The MerCruiser 120 has been running great since. The kids tube, wakeboard, and ski though not as much as they are getting older, but we still get out, cruise and discover new areas around the lake.

The last few years the floor has been getting soft, the seats had seen better days, some of the gauges starting to fail and the bilge pump has been running more. We've always checked for leaking rivets and nothing major, just a couple more each season. So at this point I thought it was a good time to fix the rivets, replace the floor, replace the seats, and make a few changes that I've seen on the forum. Was planning to have a local guy paint and maybe replace the leaking rivets and hopefully be back on the water in the summer. The last couple weeks I've been removing parts, documenting as I go. I pulled the floor today, the styrofoam was surprisingly clean with just a little dark staining on the bottom pieces towards the stern. As I was pulling the floor that would be under the front seats, I noticed the runner was leaned over. Removing that section of floor was when my worst fears were realized. 8 cracked ribs and broken runner on the port side. The ribs are cracked right where the runner attaches. I know 3 of the ribs were really loose as that's where most of the leaks were. I saw one patch on the inside starboard side towards the bow, must have been done before the family's ownership. I don't see any stress cracks in the skin while looking from the inside. Can't see anything from the outside as there are several coats of rubberized paint on the bottom. The strake on that side does have a crack where the front weep hole is and there are a few really loose rivets

Not sure I want to take this on myself since its structural in nature. I searched around the forum and didn't find anything on cracked ribs or repair. We've got a call out to a friend whose brother has been in the boat repair business to see if he knows anyone who could do the repair.

Fortunately, the only thing I've purchased so far was the front seats so I'm not out a lot of money yet should it be unrepairable. Obviously, the Captain has sentimental attachment so that is a huge factor.

This forum has been great over the years with helping me maintain the boat and hoping to get your perspective on if this is worth repairing.