We had been running for an hour, engine appeared to be running well. Engine just stopped.

Checked for spark, nothing from the coil wire. Also battery voltage was low. Engine has 1800 hours on it, coil and both fuel pumps replaced 500 hours ago. 2006 (?) model, s#OM675521.

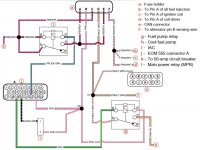

Was towed 15 miles back to the harbor. Charged the batteries, still no start. Used the Rinda software on my laptop, it showed no faults. Changed the crankshaft position sensor, still no starting. Fuel pressure was somewhat over the normal 43 psi, with the key on and obviously not running.

Any suggestions? I tried saving the computer information with Rinda, but that did not work. Thinking the Merc. computer may have a problem, am considering sending it out to High Tech Electro ECM, but I know nothing about their reputation.

Any suggestions?

Checked for spark, nothing from the coil wire. Also battery voltage was low. Engine has 1800 hours on it, coil and both fuel pumps replaced 500 hours ago. 2006 (?) model, s#OM675521.

Was towed 15 miles back to the harbor. Charged the batteries, still no start. Used the Rinda software on my laptop, it showed no faults. Changed the crankshaft position sensor, still no starting. Fuel pressure was somewhat over the normal 43 psi, with the key on and obviously not running.

Any suggestions? I tried saving the computer information with Rinda, but that did not work. Thinking the Merc. computer may have a problem, am considering sending it out to High Tech Electro ECM, but I know nothing about their reputation.

Any suggestions?

Attachments

Last edited: