websterama

Cadet

- Joined

- May 10, 2023

- Messages

- 10

I recently purchased a 2019 Chaparral 277 SSX with 100 hours on its Volvo Penta V8 380

The Sea-trial and initial launch were perfectly fine.

Literally the next day I went to start the engine and it wouldn't.

Cranks fine, but then won't catch/stay running.

Here's a video of it doing this

After posting in a Chaparral forum, somebody suggested a workaround which i have tried, and it sometimes does the trick. Putting the throttle in "throttle-only" position by hitting the button in center, and then pushing it forward to give the engine some gas before attempting to crank it. It's fiddly and sometimes requires me to jiggle it around during crank, but 50% of the time that will do it. I've also opened the fuel caps thinking maybe it was vapor locked ?

After it starts in this way, i can pull the throttle back to neutral and it purrs like a kitten.

So it doesn't idle rough, etc..

This workaround doesn't make a ton of sense to me, as this is a fuel injection system not a carb?

I've replaced the batteries, just to make sure they weren't old/tired etc.

I've checked the fuel filter (no water present), checked the fuel pressure at low/high side (after having heard that these are common failure points) and they look to me to be within norms (as a non-expert).

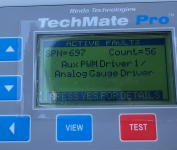

Other things people have suggested as places to look (throttle position sensor, idle control, etc.) are beyond my ability to mess with as a non-engineer I fear.

One thing to note is the boat wasn't used much last year, and was stored with half a tank of gas, which is why i started with fuel filter looking for water, etc... But it doesn't seem like that's the issue based on how well it runs once started and what i saw in fuel filter.

I'd love to be told to just take it over to the gas dock and fill it all the way with new fuel and that will fix it. But I've been to nervous about getting stuck at gas dock to do it until I've looked at other things that might be culprit.

Anyway folks told me this forum is the place to go so I'm hoping (praying) there's some simple thing I'm doing wrong or way to figure out what this is from those symptoms.

Thanks for any advice!

The Sea-trial and initial launch were perfectly fine.

Literally the next day I went to start the engine and it wouldn't.

Cranks fine, but then won't catch/stay running.

Here's a video of it doing this

After posting in a Chaparral forum, somebody suggested a workaround which i have tried, and it sometimes does the trick. Putting the throttle in "throttle-only" position by hitting the button in center, and then pushing it forward to give the engine some gas before attempting to crank it. It's fiddly and sometimes requires me to jiggle it around during crank, but 50% of the time that will do it. I've also opened the fuel caps thinking maybe it was vapor locked ?

After it starts in this way, i can pull the throttle back to neutral and it purrs like a kitten.

So it doesn't idle rough, etc..

This workaround doesn't make a ton of sense to me, as this is a fuel injection system not a carb?

I've replaced the batteries, just to make sure they weren't old/tired etc.

I've checked the fuel filter (no water present), checked the fuel pressure at low/high side (after having heard that these are common failure points) and they look to me to be within norms (as a non-expert).

Other things people have suggested as places to look (throttle position sensor, idle control, etc.) are beyond my ability to mess with as a non-engineer I fear.

One thing to note is the boat wasn't used much last year, and was stored with half a tank of gas, which is why i started with fuel filter looking for water, etc... But it doesn't seem like that's the issue based on how well it runs once started and what i saw in fuel filter.

I'd love to be told to just take it over to the gas dock and fill it all the way with new fuel and that will fix it. But I've been to nervous about getting stuck at gas dock to do it until I've looked at other things that might be culprit.

Anyway folks told me this forum is the place to go so I'm hoping (praying) there's some simple thing I'm doing wrong or way to figure out what this is from those symptoms.

Thanks for any advice!