Not sure if the boat has been used in salt water, I know the last owner used it only on fresh water and some people have said the drive etc seem in too good condition for it to have been left for long in salt water. So far I've only used it on fresh water but I do plan on using it on salt water, though I won't be leaving it moored on salt water for longer than (say) a week at a time.

I wonder if the Salt Away stuff would shift rust?

I don't think I'd want to remove the water pump just to flush the engine, if I were going to remove the water pump I'd probably pull the engine out of the boat first. But I understand your idea about being able to reverse flush if I did that.

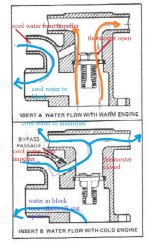

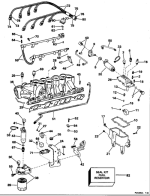

I suppose any filter would need a big enough surface area not to restrict flow if it started collecting some debris, with big enough holes not to collect tiny bits just bits big enough to cause a problem for the thermostat. One problem for the filter idea is I expect (because most vehicle engines pump to the top of the rad, bottom hose is where cooled water returns from the rad) the flow direction will be from the water pump to the stat housing then down through the wide rubber pipe to the bottom inlet? If that is true the water containing debris would already have gone past the stat before going through the filter... and if it goes past the stat the stat could be open and the debris could still get stuck in it and hold it open. But still I'd expect a filter of suitable spec to have a positive effect if placed inline with that wide diameter rubber stat to water pump pipe.

I wonder if the Salt Away stuff would shift rust?

I don't think I'd want to remove the water pump just to flush the engine, if I were going to remove the water pump I'd probably pull the engine out of the boat first. But I understand your idea about being able to reverse flush if I did that.

I suppose any filter would need a big enough surface area not to restrict flow if it started collecting some debris, with big enough holes not to collect tiny bits just bits big enough to cause a problem for the thermostat. One problem for the filter idea is I expect (because most vehicle engines pump to the top of the rad, bottom hose is where cooled water returns from the rad) the flow direction will be from the water pump to the stat housing then down through the wide rubber pipe to the bottom inlet? If that is true the water containing debris would already have gone past the stat before going through the filter... and if it goes past the stat the stat could be open and the debris could still get stuck in it and hold it open. But still I'd expect a filter of suitable spec to have a positive effect if placed inline with that wide diameter rubber stat to water pump pipe.