cassadypaul

Cadet

- Joined

- Apr 22, 2016

- Messages

- 23

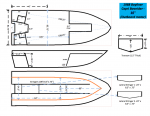

I have a 1990 Sea Ray 160 that has been in the family for about 25 years. I have been the owner for the last three. This boat is very dear to my heart. I learned how to drive a boat in it. I remember it as a child on Great Pond in Maine. We brought it home to Cincinnati about three years ago and did not get to use it last year.

The good. The upholstery is in great condition for its age. Only one pulled seam! The engine and drive are in good condition but could use a bit of reconditioning. The trailer is on new tires and is structurally sound. The gel coat is also in good condition with light oxidation.

The bad. The entire boat is SOAKED. I have tried to dry it and have not had any luck. It is my belief that the transom, stringers, and most of the floor are rotten. And not to mention the foam is waterlogged. The bottom is also a bit of a mess as far as gel coat goes but I can repair that. (very shallow dock in Maine) It will be good practice for the few nicks on open areas on the boat. The engine idles a little rough but otherwise runs well.

At this point in time I have ZERO money in the boat other than engine maintenance which I do not count. I want to do a Friscoboater style restoration. I have good mechanical skills and know how to lay up fiberglass. My biggest questions are as follows. Is it worth it? How much cost in materials am I looking at? (Ballpark? Rough idea?)

Any help or general discussion will be very helpful.

The good. The upholstery is in great condition for its age. Only one pulled seam! The engine and drive are in good condition but could use a bit of reconditioning. The trailer is on new tires and is structurally sound. The gel coat is also in good condition with light oxidation.

The bad. The entire boat is SOAKED. I have tried to dry it and have not had any luck. It is my belief that the transom, stringers, and most of the floor are rotten. And not to mention the foam is waterlogged. The bottom is also a bit of a mess as far as gel coat goes but I can repair that. (very shallow dock in Maine) It will be good practice for the few nicks on open areas on the boat. The engine idles a little rough but otherwise runs well.

At this point in time I have ZERO money in the boat other than engine maintenance which I do not count. I want to do a Friscoboater style restoration. I have good mechanical skills and know how to lay up fiberglass. My biggest questions are as follows. Is it worth it? How much cost in materials am I looking at? (Ballpark? Rough idea?)

Any help or general discussion will be very helpful.