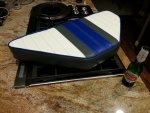

Re: 1989 Australian Flightcraft 18XLT Deck/Stringers/Upholstery Resto

Morning Vincent,

You are doing a great job considering your very humble beginnings...

For someone who has rarely sewn a button on, your upholstery work has turned out very professional looking, Nice Job!

I have just caught up with your thread and find it enjoyable, entertaining and most of all it is going to be a valuable educational tool for any who come along...

So, don't fret...we are going to jump aboard, but with so many threads about so many of us duped noobs getting in way over our collective heads, it may take a bit before all the experts around here chime in with good suggestions on how to proceed...

The last couple of suggestions by "mrdjflores" and "woodonglass" are spot on...

Get a Photobucket account and do the pics with that...

Air bubbles are definitely never good, but they will happen...my personal preference is to avoid them as much as possible when doing structural layups, such as stringers, bulkheads and transoms...even then they happen...my solution, if the air bubble isn't too huge, is to use a rotary type tool with a small rounded carbide bit, to grind out the offending air bubble, then re-fill the cavity with thickened resin [aka, Peanut Butter]...then lay some mat over the area...

Also, when working in less than comfortable positions, such as a vertical or upside down section, you can set your self up with some temporary type of clamp/support system using a variety of any or all of the following...

Cardboard covered in wax paper or as you stated earlier, mylar, to lay against the repair, some wood backers to hold up the cardboard to the repaired area, C-clamps, straps, or even some screws through the first repair to hold everything together, then when it is set up, filled with PB, and additional layers of matting/cloth...

Not sure if you are aware of the technique of using your chip brush as a primary tool when applying cloth, but you can use it to gently jab, jab, jab at the matting to help pop bubbles and make it settle, you can also get what is known as a bubble buster roller...it looks like a bunch of pizza cutting wheels mounted on a common shaft and used to gently roll over the wet area and "Bust Bubbles"

Even though it will never work as well as having 12 limbs, you can usually get creative ways to support your repairs in progress with some of the above ideas...

Just try and do a couple of dry runs/rehearsals with your intended repair, before actually going in for the kill...that way you will know what to expect...well, sort of...

Best of luck on your journey and we'll be along to help any way we can...

Regards,

GT1M