Hi All,

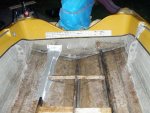

This is a thread about work I am doing on my nautiglass. It's a 4.6mtr fiber glass half cabin boat I bought 4 or 5 years ago. It's always had a pretty spongy floor and has been taking on water for the last year or so. After each trip out water has been coming out of the bottom plug with bits of what looks like rotten black plywood. Not good eh..... Well a couple of weeks ago I decided it was well past being safe on the water and being one to always enjoy doing something once at least though I'd try my hand in glassing etc and fixing it. I'll also be addressing the leaks in the hull :>

I will start adding some posts of what I have done each day.

The Boat. I probably should just buy another one, but I really like this and I think I have that 1st boat thingy!

This is a thread about work I am doing on my nautiglass. It's a 4.6mtr fiber glass half cabin boat I bought 4 or 5 years ago. It's always had a pretty spongy floor and has been taking on water for the last year or so. After each trip out water has been coming out of the bottom plug with bits of what looks like rotten black plywood. Not good eh..... Well a couple of weeks ago I decided it was well past being safe on the water and being one to always enjoy doing something once at least though I'd try my hand in glassing etc and fixing it. I'll also be addressing the leaks in the hull :>

I will start adding some posts of what I have done each day.

The Boat. I probably should just buy another one, but I really like this and I think I have that 1st boat thingy!