Thank you guys for your all inputs. I just wish I knew someone who either has my same motor or has actually had it in their hands and could definitively say yes, you have a thermostat, yes you have a thermal sensor, and yes there is or is not a “limp mode” on this model. I can’t physically see it and don’t have the experience to rely on. Thanks again…even

I appreciate that, and as much as I should have a warning horn if available…I’m still trying to track down possible reasons why my motor is bogging down after running great for 20 minutes. If there actually is a Limp Mode and associated parts it would be very helpful.

UPDATE: I went back to my fuel pump. I had replaced the diaphragm awhile back before this weird issue started. At that time my motor was surging at idle. I read that it was a classic fuel pump issue, so I obtained a replacement diaphragm from a local repair shop. So until now I had ruled out the fuel pump regarding my recent issues since I had replaced the diaphragm, right? Until recently when someone mentioned that there is a better kit that also includes the check valves for these triangular pumps. With new kit in-hand I pulled off the pump assembly and discovered that the gasket on my new kit was slightly different than the one I had replaced initially. See Image (it didn't seem to match perfectly)Thank you guys for your all inputs. I just wish I knew someone who either has my same motor or has actually had it in their hands and could definitively say yes, you have a thermostat, yes you have a thermal sensor, and yes there is or is not a “limp mode” on this model. I can’t physically see it and don’t have the experience to rely on. Thanks again…even

I appreciate that, and as much as I should have a warning horn if available…I’m still trying to track down possible reasons why my motor is bogging down after running great for 20 minutes. If there actually is a Limp Mode and associated parts it would be very helpful.

Below is with the new gasket (perfect match)

After putting it back together, I went to the lake. Although I had a little issue with starting, I idled out and the motor ran flawlessly for over an hour non-stop. So it looks like my haunted problems are over. Could it have been the fuel pump gasket (or check valves) all along? Sure seems that way.

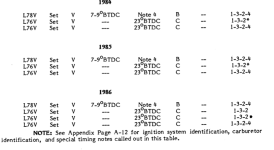

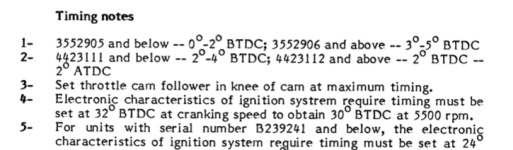

My only issue now is my idle. Before heading back to the boat launch, I decided to adjust my idle up a bit since I was having a hard time keeping it running when I launched. After I adjusted it however, I had a really hard time starting, and it hesitated pretty bad when I tried to pop out of the hole. I attempted to adjust the idle mixture screws (duel "C" carbs on this 1985 merc). It seemed to come out of it. But I'm still having to push in the choke every time to get it started. My manual states that the rpms should be between 700-800 before adjusting the idle mixture screws. Then after adjusting mixture screws and a successful response, adjust the idle stop for 500-600 rpms. I don't really understand the precedence of that. Please comment. Seems as though my attempt to adjust the idle up after it had been running so great, threw off my idle mixture.

Also, with my issue of hard starting and keeping it running when I initially pop it into gear, would you agree that I am probably running too lean?

Thanks in advance!