mvanek21

Seaman Apprentice

- Joined

- Apr 12, 2024

- Messages

- 37

Hi all,

First off, I'd like to thank everybody on here for all the help I've received on other threads regarding other motor/electrical issues I've now successfully repaired.

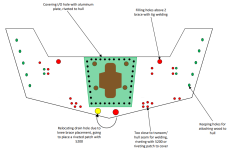

This post will be about an aluminum boat I've purchased in hopes to cut open the closed bow, and transform it into an open bow designed for an extra pedestal seat for walleye jigging. I plan on including pictures as I progress through this project in hopes of receiving tips/tricks to help make it as successful and seamless as possible. I would like to construct a livewell into this boat as well if its doable once I go through the hull and ensure all the rivets/structural pieces are intact. The boat is a 1981 Springbok 18', previous owner said it would handle up to a 115 with no problem, just looking for some feedback as to what the max HP rating would be, nothing urgent as the hull itself is the priority and powering it will be one of the last steps. I've included some pictures below of the hull.

Any feedback/tips/tricks/advice is all greatly appreciated...

First off, I'd like to thank everybody on here for all the help I've received on other threads regarding other motor/electrical issues I've now successfully repaired.

This post will be about an aluminum boat I've purchased in hopes to cut open the closed bow, and transform it into an open bow designed for an extra pedestal seat for walleye jigging. I plan on including pictures as I progress through this project in hopes of receiving tips/tricks to help make it as successful and seamless as possible. I would like to construct a livewell into this boat as well if its doable once I go through the hull and ensure all the rivets/structural pieces are intact. The boat is a 1981 Springbok 18', previous owner said it would handle up to a 115 with no problem, just looking for some feedback as to what the max HP rating would be, nothing urgent as the hull itself is the priority and powering it will be one of the last steps. I've included some pictures below of the hull.

Any feedback/tips/tricks/advice is all greatly appreciated...