GT1000000

Rear Admiral

- Joined

- Jul 13, 2011

- Messages

- 4,916

Sam, oh Sam, oh Sam...

You da man!

Been following along this speed boat resto since it followed you home and I am digging the lines...

The wood would look Amazing!

I have no doubt it will turn out to be, yet another "sphelps" masterpiece!

I read where you asked about the bent trailer tongue and the metallic finish on the hull...

First the bent trailer tongue...

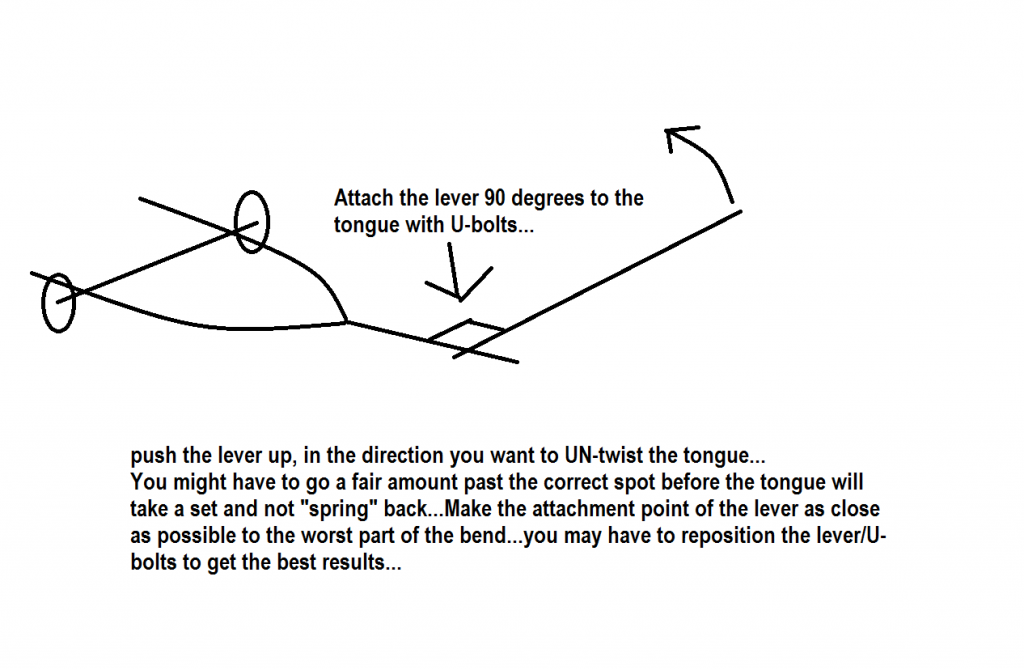

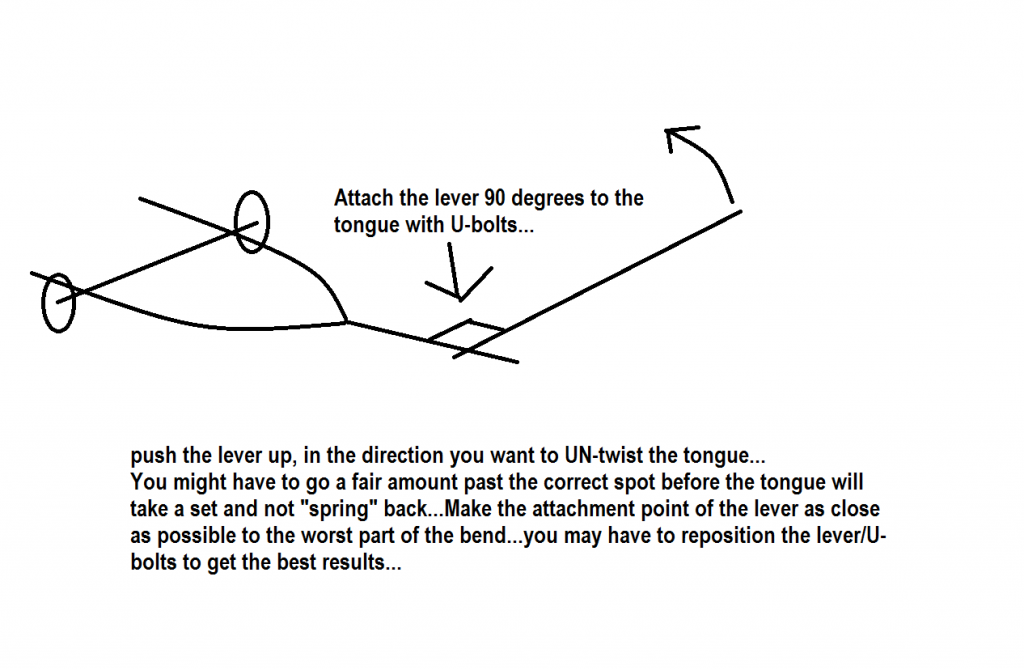

If you get a long enough piece of heavy tubing/pipe or square steel, you could clamp it to the tongue using some U-bolts at 90 degrees to the tongue, then, provided the leverage of the persuader bar doesn't lift the wheels off the ground, in which case you would have to weigh it down or anchor the trailer frame to the ground, you should be able to twist the tongue back into alignment with no ill effect on the strength of the frame...

Depending on the material its made of, I would avoid using heat of any kind...too many variables to deal with...physical force/pressure should put that back in alignment...

And as far as the metallic finish, you should be able to get good results by practicing with your spray gun, some metal flake and some inexpensive clear coat...

Mix up a small batch and spray on some surfaces all while trying to achieve an even layer of metallic particles...when dry, check your results in full, direct sunlight...adjust your technique until you feel confident with the patterning of the metal flake/metallic.

Make sure you practice on both vertical and horizontal surfaces to be sure to use the same technique...

Your goal is to get an even pattern of flake with the least amount of coats ...

Then, if/when you decide to refinish the Borum, get the actual materials you are going to spray, do a couple of small test patterns to get familiar with the product, and go to town...

The basic formula for shooting flake is a compatible primer base, base color, flake mixed in the clear, final topcoat of clear...make sure everything comes from the same manufacturer to avoid compatibility issues...

Some variations use a translucent base color with flake mixed in...

Keep in mind that shooting flake is a one time proposition and the entire project NEEDS to be done at the same time so that consistency in flake patterning rules...

Custom flake jobs are rarely ever "Matched" due to the way each individual shoots the product, along with number of coats, types of paints, etc, etc...unless the original painter has a really good memory, or documented each step, even they would have a hard time repeating the finish...

Well, one thing's for sure...

I'll be following along...

All the best,

GT1M

You da man!

Been following along this speed boat resto since it followed you home and I am digging the lines...

The wood would look Amazing!

I have no doubt it will turn out to be, yet another "sphelps" masterpiece!

I read where you asked about the bent trailer tongue and the metallic finish on the hull...

First the bent trailer tongue...

If you get a long enough piece of heavy tubing/pipe or square steel, you could clamp it to the tongue using some U-bolts at 90 degrees to the tongue, then, provided the leverage of the persuader bar doesn't lift the wheels off the ground, in which case you would have to weigh it down or anchor the trailer frame to the ground, you should be able to twist the tongue back into alignment with no ill effect on the strength of the frame...

Depending on the material its made of, I would avoid using heat of any kind...too many variables to deal with...physical force/pressure should put that back in alignment...

And as far as the metallic finish, you should be able to get good results by practicing with your spray gun, some metal flake and some inexpensive clear coat...

Mix up a small batch and spray on some surfaces all while trying to achieve an even layer of metallic particles...when dry, check your results in full, direct sunlight...adjust your technique until you feel confident with the patterning of the metal flake/metallic.

Make sure you practice on both vertical and horizontal surfaces to be sure to use the same technique...

Your goal is to get an even pattern of flake with the least amount of coats ...

Then, if/when you decide to refinish the Borum, get the actual materials you are going to spray, do a couple of small test patterns to get familiar with the product, and go to town...

The basic formula for shooting flake is a compatible primer base, base color, flake mixed in the clear, final topcoat of clear...make sure everything comes from the same manufacturer to avoid compatibility issues...

Some variations use a translucent base color with flake mixed in...

Keep in mind that shooting flake is a one time proposition and the entire project NEEDS to be done at the same time so that consistency in flake patterning rules...

Custom flake jobs are rarely ever "Matched" due to the way each individual shoots the product, along with number of coats, types of paints, etc, etc...unless the original painter has a really good memory, or documented each step, even they would have a hard time repeating the finish...

Well, one thing's for sure...

I'll be following along...

All the best,

GT1M