So, Saturday I decide I'm gonna finish the deck inside the boat. I'm very well prepared; Had a heater running in the boat for a couple days. All my cloth and matt is cut to fit, labeled, and stacked in the correct order. I've got brushes, rollers, acetone, bubble busters, gloves, rags, etc., moved into the boat. I have enough resin to complete the job.....I'm all set!

I wetted out the deck boards, and waited for it to tack up, then I started glassing. I put down the 1708 tabbing, then the first layer of CSM, and about 90% of the second CSM layer, wet on wet, and I RAN OUT OF MEKP!!!!!!! WHAT???!!! :rant:I couldn't believe it! How can I be soooooo prepared and not realise I was running short of catalyst? :frusty: I still needed to lay a strip along the starboard side, which will be under the galley cabinets, and a couple small pieces under the bathroom pan at the port aft, and I was stuck. I phoned the fella at the fiberglass shop in town and he brought me some MEKP on his way home from work, (luckily he was working on Sat).

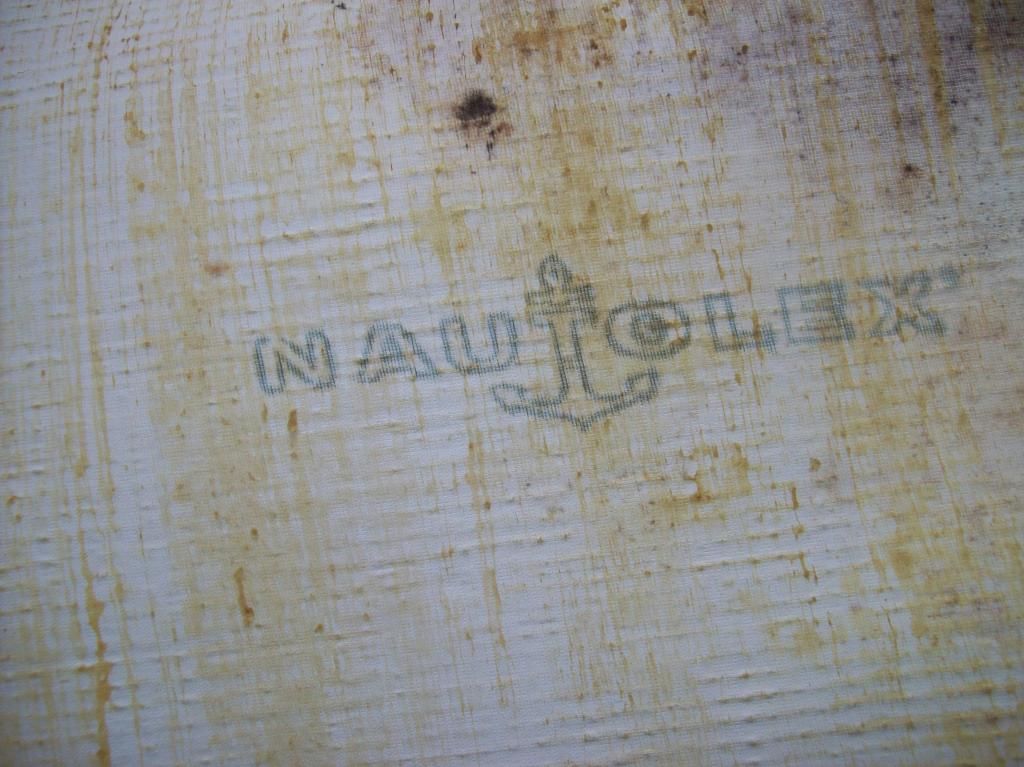

Here's how it looked Sat. You can kinda see the lighter single matt layer on the right of the pic,

Sunday morning I got back at 'er. I wiped down with acetone and finished laying the CSM, waited for it to tack up, then rolled on the first coat of gelcoat with no wax. When it tacked up I applied the second coat with wax and crushed walnut shells.

And here's looking aft from the V-berth,

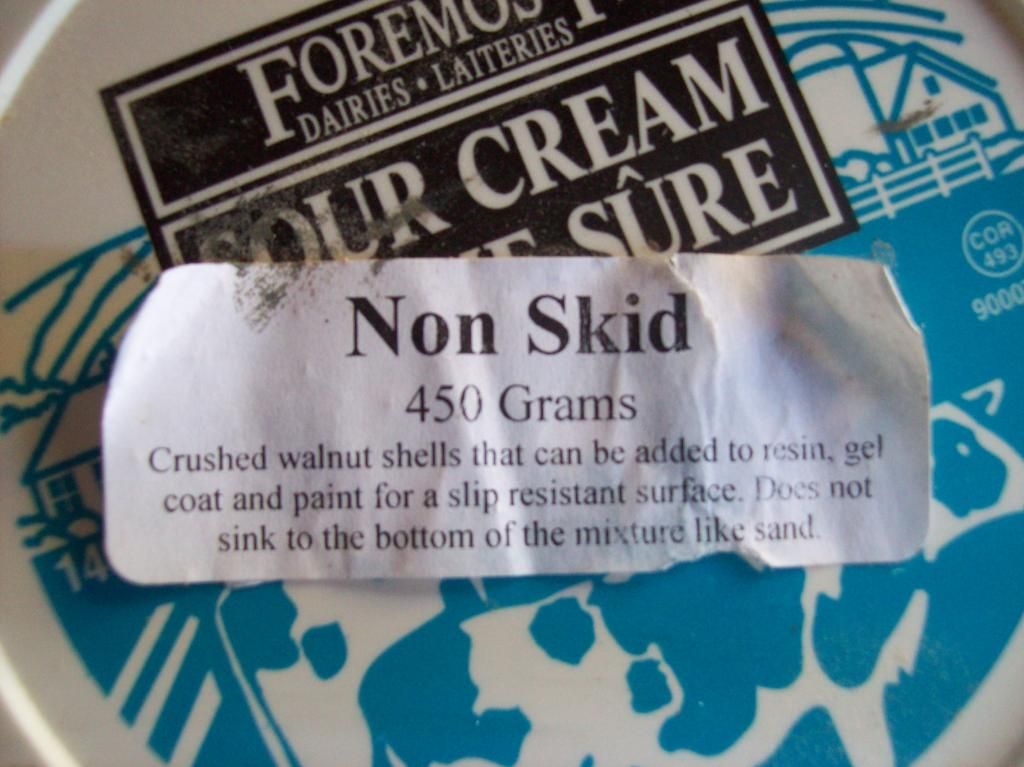

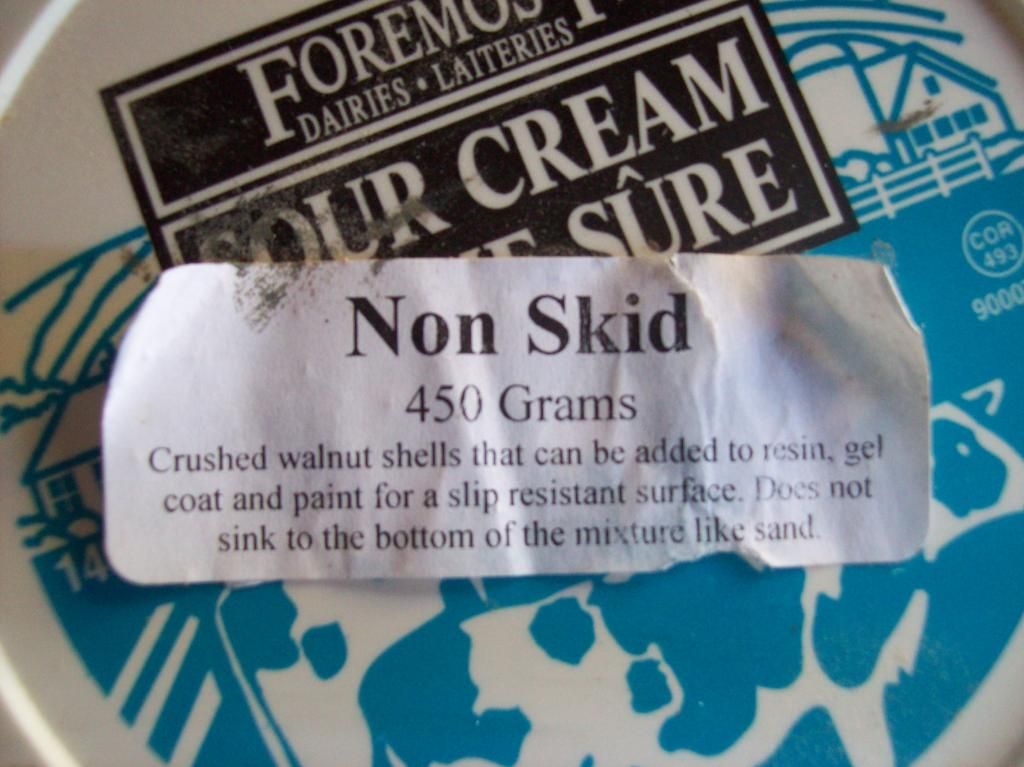

This is the grit I added,

I couldn't find any info on how much to use, so I went with 10% by volume. Wax was 4% and MEKP at 2%.

Yesterday I cleared all the holes and openings, and installed the deck plate above the fresh water connections. I also replaced the gas deck fill fitting and installed the fill hose and the ground wire. Then I did a light rough and scruff on the bottom of the step down into the V-berth because on Sunday I had started rolling on some gelcoat with grit when I remembered that I hadn't ground the area after previously applying a waxed coat. I have enough gelcoat and grey dye left to redo it, this time with grit. And I have enough MEKP....now.

The final count of resin used.......19 US gallons, (72 liters). I got one of the cans from the fiberglass shop after he had used one gallon.