Curtis W.U.

Cadet

- Joined

- Apr 29, 2018

- Messages

- 17

I have a 1979 115 hp 2 cycle 6 cylinder inline mercury out board.

I am refurbishing the 16 ft. Hydra sports bass boat. I have everything completed except the engine repair.

What I have done and tried is as follows:

1. Clean carbs (would run at higher rpm but not idle no matter how the carbs was set)

2. Checked compression had 115 to 120 on all cylinders.

3. Cheked plug firing and all cylinders are firing.

4. Had a lot of play in from throttle lever to carb/timing linkage (could not get new linkages due they are no longer produced) So I decided to use a light spring to keep linkage loaded so there would be no advance of spark at idle.

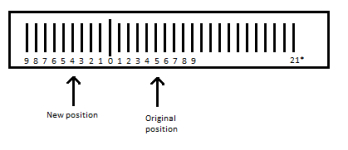

Had it running and idling but it was rough so tried adjusting the carbs and got some of it out then made a mistake and tried adjusting the timing advance lol now it will not run unless it is higher idle speed. can't seam to find the right point for the advance/carb setting.

How do you adjust the timing advance and carburetors for this outboard.

Btw I am a senior electronics tech and have retired from industry where I have 45 years experience in Electronics/electrical/mechanical so I should be able to follow any technical instructions.

Thank you

I am refurbishing the 16 ft. Hydra sports bass boat. I have everything completed except the engine repair.

What I have done and tried is as follows:

1. Clean carbs (would run at higher rpm but not idle no matter how the carbs was set)

2. Checked compression had 115 to 120 on all cylinders.

3. Cheked plug firing and all cylinders are firing.

4. Had a lot of play in from throttle lever to carb/timing linkage (could not get new linkages due they are no longer produced) So I decided to use a light spring to keep linkage loaded so there would be no advance of spark at idle.

Had it running and idling but it was rough so tried adjusting the carbs and got some of it out then made a mistake and tried adjusting the timing advance lol now it will not run unless it is higher idle speed. can't seam to find the right point for the advance/carb setting.

How do you adjust the timing advance and carburetors for this outboard.

Btw I am a senior electronics tech and have retired from industry where I have 45 years experience in Electronics/electrical/mechanical so I should be able to follow any technical instructions.

Thank you

Last edited: