Well, it's been a very long time. I don't know how I forgot about IBoats, but I am back again. I have been taking some pictures along the way.

Put a nice little console panel in, as well as a radio.

Reinforced the pilots steering console. I also had to make a little mount for the radio.

I drew up the mirrored version of the pilots station and had it lasercut/bent out of aluminum.

I made a bracket to hold my kicker in the up position that wont fall when trailering.

Took the boat to a nearby island this last summer.

I also started constructed the windshield from 0.100" 5052 aluminum. Scrap sheet stock that I had on hand.

I cut out the window areas using a jig saw.

To put the windows in, I used the rubber locking product. I happened to design my window off of a specific size and was given the incorrect rubber. Which caused me to break a glass panel during install, so I took it to a shop and payed them $200 to install it. When I picked it up they let me know my glass was about 0.25 inches to big and they had to grind it down a ton to fit.

Somewhere around the same time as the windows, I managed to find a trap puller for 50 bucks!

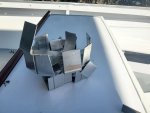

I also managed to find a government posting for 14 commercial crab traps. They were about 42" in diameter. I used them a few times (only 4) and realized they are just way to big, So I sold them for a profit (+400ish$).

Picking them up was fun... Luckily I had recently purchased a truck.

But yeah, not much else has happened.

I recently put an order in for a cheap bimini cover. I am going to make side and a back from it so that its an enclosed soft cabin that can be heated. Winter fishing gets pretty cold!

I will try to post more regularly again.