gm280

Supreme Mariner

- Joined

- Jun 26, 2011

- Messages

- 14,605

Re: 1976 Johnson 40 HP Outboard Complete Rebuild

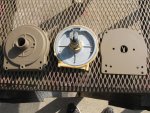

Okay folks, it is back to this project now as well. I have been working some other home projects that took time from this motor rebuild, but I am now back to working on this motor now again. I have completely primed most all the aluminum parts now with Zinc Chromate primer and am waiting for the temps to get around 65 to 70 degrees to spray the K36 PPG sandable primer and start sanding out any imperfections. I had a very hard time locating that zinc chromate primer and the only place I was able to find it (not counting the web) was at our NAPA Auto parts dealer. A bit pricy but well worth it. I should be able to spray the K36 primer in the next week it seems according to the weather reports around here. In the mean time I have cleaned almost all the hardware in preparation for the reassembly as well. Every nut, washer and bolt have been cleaned and wire brushed on my grinder/wire brush grinder setup to get all the old dried up oils, grease, and sealer material out of the threads. So I will post some new pictures showing this stage in a few days. I did drill and tap the top of the cylinder block to install a tell tale outlet and all worked out very nice too. I still have to rework the wiring harness for the engine with new connector ends and wire as needed. Old cracked insulation on some of the wires is worn and needs to be replaced with new wires. Then rewrapped with new tape to seal the harness. But this is the stuff I like to do so no big problem. Every part I came across that was not in like new condition has been ordered and replaced. I want this rebuild to go like a new motor when finished. Considering the cost of a new 40 HP engine these days, I’d say I am getting a super good deal as well... I now am looking at other boat and motor projects and I haven’t even finished this one yet...Go figure! I do have one question for anybody reading. I have completely cleaned and even sand blasted all the parts to metal and priming and repainting them back to new finishes with the exception of the carb. I want the carb to look new as well but not sure what finish to apply. Anybody have a good idea to deal with the carb finish? Should clean it and then apply just a clear coat finish or spray it with some new type carb finish spray? Wondering...

Okay folks, it is back to this project now as well. I have been working some other home projects that took time from this motor rebuild, but I am now back to working on this motor now again. I have completely primed most all the aluminum parts now with Zinc Chromate primer and am waiting for the temps to get around 65 to 70 degrees to spray the K36 PPG sandable primer and start sanding out any imperfections. I had a very hard time locating that zinc chromate primer and the only place I was able to find it (not counting the web) was at our NAPA Auto parts dealer. A bit pricy but well worth it. I should be able to spray the K36 primer in the next week it seems according to the weather reports around here. In the mean time I have cleaned almost all the hardware in preparation for the reassembly as well. Every nut, washer and bolt have been cleaned and wire brushed on my grinder/wire brush grinder setup to get all the old dried up oils, grease, and sealer material out of the threads. So I will post some new pictures showing this stage in a few days. I did drill and tap the top of the cylinder block to install a tell tale outlet and all worked out very nice too. I still have to rework the wiring harness for the engine with new connector ends and wire as needed. Old cracked insulation on some of the wires is worn and needs to be replaced with new wires. Then rewrapped with new tape to seal the harness. But this is the stuff I like to do so no big problem. Every part I came across that was not in like new condition has been ordered and replaced. I want this rebuild to go like a new motor when finished. Considering the cost of a new 40 HP engine these days, I’d say I am getting a super good deal as well... I now am looking at other boat and motor projects and I haven’t even finished this one yet...Go figure! I do have one question for anybody reading. I have completely cleaned and even sand blasted all the parts to metal and priming and repainting them back to new finishes with the exception of the carb. I want the carb to look new as well but not sure what finish to apply. Anybody have a good idea to deal with the carb finish? Should clean it and then apply just a clear coat finish or spray it with some new type carb finish spray? Wondering...