Hello All,

I just recently came into ownership of a 1976 Glastron T156 for a minimum amount of money; to say the least, it needs a little work. At the time of purchase it was operational. The actual purchaser of the boat bought the boat for the motor then basically handed the boat to me. I like have the project to work on but as for most, the money situation is tight so I am looking to save pennies where I can, but at the same time having a quality product. I do have a little experience repairing boats, I recently bought a '68 MonArk McFast and replaced the floor and did minimal fiberglass work.

SO, back to my current project that I need some guidance on:

Floor - I will attach a picture, but there is a floor but it seems to need maybe another sheet of plywood? I want to know what is the cheapest wood I could get a way with using and yes I do plan on putting carpet on the floor.

Seating - The boat has no seats behind the console. I want to put in a single seat for the driver and I want to build a bench seat on the passenger side and along the rear of the interior of the boat. Nothing fancy, literally all I want to do is make the bench seats from scratch. My plan is to put a couple speakers under the edge of the front of the seats. So, my question is, what is the cheapest wood I can use to make some durable seats and yes I plan to put some padding and having them wrapped when finished. Also, side issue I just thought about, do you think the sheer weight of the wood will cause an issue with how the boat floats and drives?

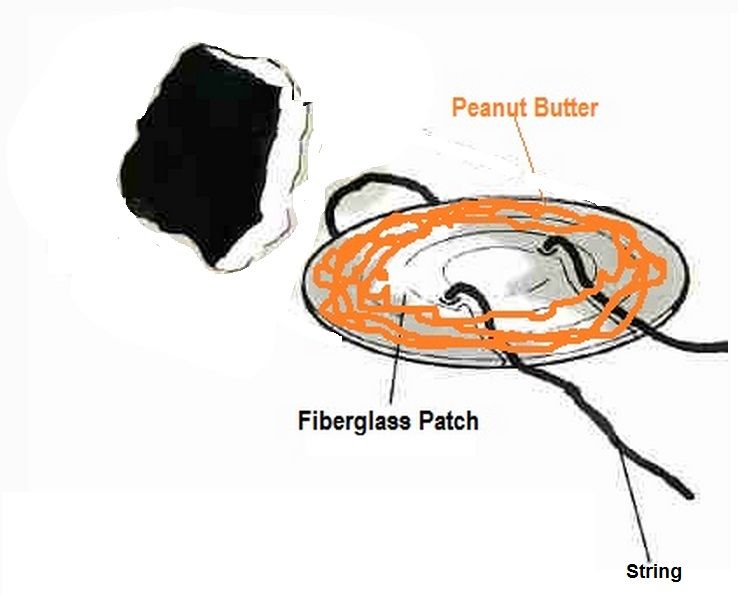

Holes/cracks - The boat has some gashes in the hull (not complete holes), some cracks from old age and it does have some possible old screw holes in the topside. I plan on removing the remaining snaps on the top side for what I can only assume would have been for some sort of cover at one point and filling those in along with the cracks and gashes. Do you think these holes can just be filled with bondo? Or do I need to use something else? The one problem I can foresee would be the fact that some of the holes are under the rail so I dont have access to the back side. And in the one picture you can see where they put in a fiberglass patch, I plan to correct it, but I will need some advice on how to paint it.... See next paragraph below.

Painting - I really want to repaint this boat; I want to come up with my own paint scheme, but I am thinking it may be too large of a task. Let's assume I muster the courage to try to repaint this boat ..... is there a type of paint that I can get away with using or do I have to use marine grade paint. YES, I KNOW, marine grade is the SMARTER route to go here, but I am not necessarily worried about long term. At most, I want to get a year or two out of it then sell it. I read on another forum that a guy used some Rustoleum spray paint and it worked out pretty well for him. Thoughts?

I know I asked a lot of questions and I appreciate any and all help and yes I know, you get what you pay for ..... :happy:

I just recently came into ownership of a 1976 Glastron T156 for a minimum amount of money; to say the least, it needs a little work. At the time of purchase it was operational. The actual purchaser of the boat bought the boat for the motor then basically handed the boat to me. I like have the project to work on but as for most, the money situation is tight so I am looking to save pennies where I can, but at the same time having a quality product. I do have a little experience repairing boats, I recently bought a '68 MonArk McFast and replaced the floor and did minimal fiberglass work.

SO, back to my current project that I need some guidance on:

Floor - I will attach a picture, but there is a floor but it seems to need maybe another sheet of plywood? I want to know what is the cheapest wood I could get a way with using and yes I do plan on putting carpet on the floor.

Seating - The boat has no seats behind the console. I want to put in a single seat for the driver and I want to build a bench seat on the passenger side and along the rear of the interior of the boat. Nothing fancy, literally all I want to do is make the bench seats from scratch. My plan is to put a couple speakers under the edge of the front of the seats. So, my question is, what is the cheapest wood I can use to make some durable seats and yes I plan to put some padding and having them wrapped when finished. Also, side issue I just thought about, do you think the sheer weight of the wood will cause an issue with how the boat floats and drives?

Holes/cracks - The boat has some gashes in the hull (not complete holes), some cracks from old age and it does have some possible old screw holes in the topside. I plan on removing the remaining snaps on the top side for what I can only assume would have been for some sort of cover at one point and filling those in along with the cracks and gashes. Do you think these holes can just be filled with bondo? Or do I need to use something else? The one problem I can foresee would be the fact that some of the holes are under the rail so I dont have access to the back side. And in the one picture you can see where they put in a fiberglass patch, I plan to correct it, but I will need some advice on how to paint it.... See next paragraph below.

Painting - I really want to repaint this boat; I want to come up with my own paint scheme, but I am thinking it may be too large of a task. Let's assume I muster the courage to try to repaint this boat ..... is there a type of paint that I can get away with using or do I have to use marine grade paint. YES, I KNOW, marine grade is the SMARTER route to go here, but I am not necessarily worried about long term. At most, I want to get a year or two out of it then sell it. I read on another forum that a guy used some Rustoleum spray paint and it worked out pretty well for him. Thoughts?

I know I asked a lot of questions and I appreciate any and all help and yes I know, you get what you pay for ..... :happy: