alipinski397

Seaman

- Joined

- Sep 3, 2013

- Messages

- 63

So last fall I had used the previous Mariner for a few months before starting the rebuild. One of the things that bothered me was the height of the steering wheel and throttle controls with this particular console setup.

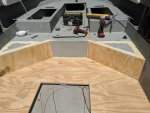

So i wanted to raise up the console to a better height for me. This is what I came up with.

This base will raise the console about 4". I also built it with a "toe kick" all the way around for more foot room when moving around it once its mounted in the boat. I think this will really make a noticeable difference in getting from front to back along the console.

Its got a few coats of spar and some Behr deckover to match the floor.

So i wanted to raise up the console to a better height for me. This is what I came up with.

This base will raise the console about 4". I also built it with a "toe kick" all the way around for more foot room when moving around it once its mounted in the boat. I think this will really make a noticeable difference in getting from front to back along the console.

Its got a few coats of spar and some Behr deckover to match the floor.