It's been a busy week at work. Time for an update on our progress last weekend.

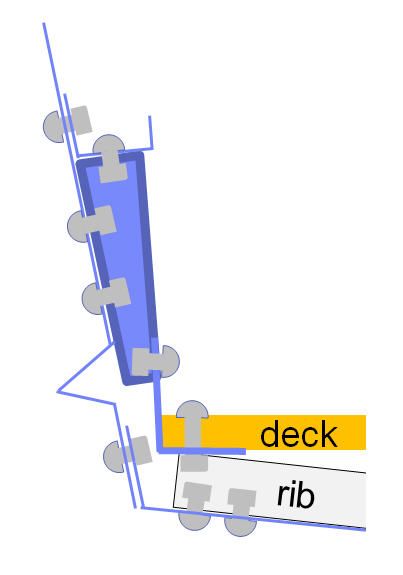

We got the new transom cut, fit, and laminated. No real problems to speak of.... yet. New deck got cut and fitted. Left stringer was patched and and riveted back to the ribs. Is there a consensus on the best way to reinforce the seams between the deck boards? PO had a piece of 1/16 inch aluminum running between the stringers at the seams. That didn't seem to do much, but I don't think anything would have considering the left stringer was just lying on the bottom of the hull.

We also got the boat off the trailer and on blocks so my brother in law can work on the trailer. I was happy with the work we got done but wasn?t happy with the unexpected work that showed up.

Now on to the two most pressing issues:

1) The cracked spray rail: I understand I need to reinforce the hull in this area (or all over). Before I do that, should I remove all of the Marine-Tex (or maybe 5200??) that is currently slopped on there to see what I'm really dealing with, OR should I leave the inside alone and sand the outside smooth and repatch as needed before painting? I will say that we put a lot of water in the hull during our leak test and verified that the current patch did not leak. Assuming it is Marine-Tex and I should remove it, what is the best way? I have read that heating it with a torch makes it pliable and easier to remove. I just don't want to warp or damage the hull by using heat. Any advice? That goes hand in hand with my next question: If I have to completely clean the goop away, should I repair the crack with Marine-Tex and/or 5200 or use a torch and aluminum brazing rods?

I am having a hard time finding other people's approach to reinforcing their hulls. WM, your approach is rock solid, but I will keep looking for different solutions before I make a move.

2) The leaking keel strip: WM, thanks for confirming that those holes are supposed to be there. They looked too perfect to be accidental, but I don't have much faith in the PO. The leak test revealed about 15-20 leaky rivets, most of which were by the damaged spray rail. The good thing is that I don't think any of the ribs are cracked. It?s worth noting that I did not gluvit the inside seams before the test. Everything that leaked will be replaced. That being said, I don't think there is any way that all of the water in the keel strip came from rivets leaking down the hull and into it. The hole in the keel strip was leaking before any of the rivets above it started leaking. The amount of water dripping from the hole also increased as the hull filled up with more water and the water pressure built up. When I would put my finger over the hole and plug the leak, water would come billowing out the top of the keel strip at a rate that exceeded all of the leaky rivets combined. If water was only entering from the outside, I can?t see how that would happen. I still think water is entering the keel strip from inside the boat? somewhere.

Thanks again for any advice.

One thing that I just realized and is equal parts funny and disconcerting is that this page has a decent amount of views and not one single person has said anything along the lines of "nice looking boat." Ha!