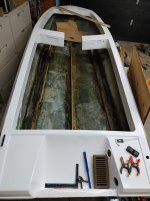

I purchased a 'boat' from an auction, called 'Photos Posted from Every Angle! - Take a Gamble & Bid Away!' Actually there are only 2-3 PS photos showing the outside. It's actually a project boat, shown in the pictures.

I decided to complete the restoration project by my self after a few days struggle.

The transom was not cut open by the previous owner, I thought I should check the condition. I cut a 2"X3" hole on the bottom right from outside. The wood is still solid. I then checked the bolt holes with a picker, found it's a little bit rotten.

I hesitated to cut the transom because too much work involved, money and time. Plus I am not sure whether I can do a good job.

I am glad I cut the transom one week later. The middle section is totally rotten, other than that, still in OK condition.

I do understand why the drain hole is not in the lowest position? The will be standing water even I raise the jack to its maximum height.

I decided to complete the restoration project by my self after a few days struggle.

The transom was not cut open by the previous owner, I thought I should check the condition. I cut a 2"X3" hole on the bottom right from outside. The wood is still solid. I then checked the bolt holes with a picker, found it's a little bit rotten.

I hesitated to cut the transom because too much work involved, money and time. Plus I am not sure whether I can do a good job.

I am glad I cut the transom one week later. The middle section is totally rotten, other than that, still in OK condition.

I do understand why the drain hole is not in the lowest position? The will be standing water even I raise the jack to its maximum height.