Hello again,

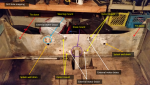

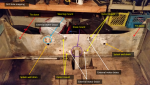

I have successfully removed the splash well and transom. I have been taking a lot of pictures because right now things that appear to be obvious may not be so obvious in six months from now when I am trying to put it together. A classic example of that would be all the holes in the transom. I ended up taking a photo and labeling all the holes, same with screws/bolts and nuts in weird places. I have some examples of my anal activity below.

My splash well is in pretty rough shape, same for that keel knee. The aluminum looks pretty thin for welding. I am thinking of going to a machine shop and have a new one fabricated. Open to suggestions on that topic.

I thought about drilling out the keel knee brace, but then I thought I would simply reinforce it. Pictures below:

I have a couple of Tupperware containers full of screws, nuts and bolts etc. I am using this system to help me remember where they all go when it comes time to put things back together. I only shared one with you, there are more (many many more).

Pretty sure this is one of two bolts along the bottom that holds the external brace to the back of the transom.

The old fuse box was located here. I am thinking that I want to replace the fuse box with something newer. I would also re-position it, I did not like all the wires hanging down around the fuel tank.

External back brace

External back brace: terms that I come up with when I don't know the proper nomenclature!

Okay this worked really well! Once again Gordy came over with another brilliant idea. We reinforced the deck boards with some scrap lumber, anything should work. We put a bottle jack on top of that, and then we screwed a piece of 2x6 into the the face of the transom. Note that the bottle jack is on an angle. We did this to both sides, jacking one side until it started to loosen, and switching to the other side. Once it "broke its seal" we just lifted it out. Worked like a charm!

You can see just how messed up the knee brace is. Potential solution is two down.

I was thinking that I could fabricate a right angle brace for both sides of the knee. Drill the holes out and rivet the brace to the sides of the knee. I could then drill out holes that would match up with the holes in the transom to accept the bolts and nuts.

Thoughts?

Again this is for my memory. There are holes in this transom that do not need to be there, so I will fill and sand those at a later date.

Does anyone know of a good aluminum cleaner? There is a little rust and corrosion on the inside of the transom that I would like to clean up.

Next step will be to remove the deck boards and the foam.