Hi all. Long time no type! Had another project here but it kinda fizzled out (as many do). As luck would have it, I have another project! Yay me!! It's a 1974 Reinell Closed Bow Ski Boat. Equipped with a Johnson 115 and came with a nice trailer. All for 600 smackers. It has issues though that I knew about up front. Upon getting into it, it has turned out to be a bit more than expected (of course). The boat was filled with water at some point and became so heavy that the front wobble rollers on the trailer cracked the sides of the hull at their contact points. Opening up the area of the floor where the cracks were located revealed that a new floor was in order as well. Nothing new there. I have pics, and of course, questions to go along with them.

First, a shot of the boat...

The exterior of the cracks...

The interior of the cracks...

The areas of the floor that I cut the access holes...

So, ok, here come the questions...

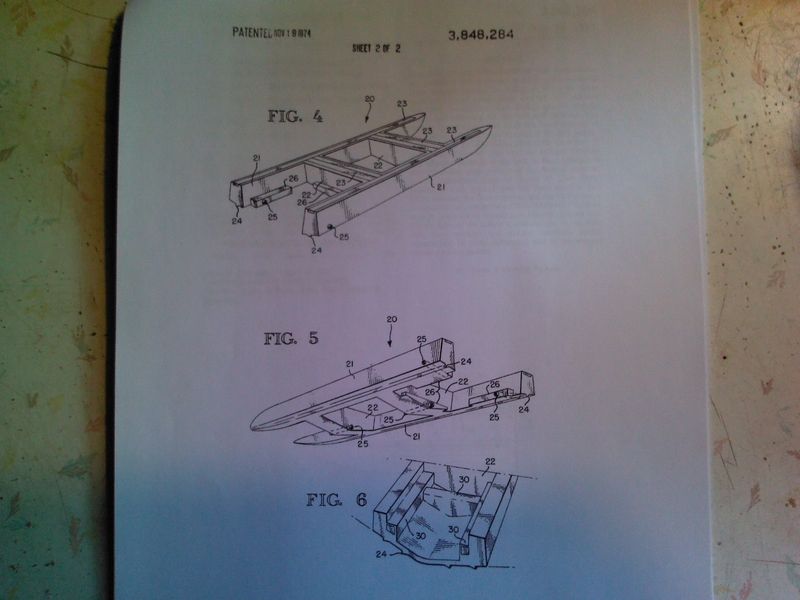

On the exterior where the cracks are, the fiberglass has been pushed in creating a depression around the cracks. Does anyone think I could get away with just building up the depression with glass on the exterior and reinforce on the interior, or should I cut the whole thing out and start from scratch? There's a bit of an issue with cutting the whole thing out because of the way the stringers were done in this boat. There appears to be a foam support for them as seen in the interior shots. I would expect that if I were to cut the cracks out, I would have to replace the foam as well. Not quite sure how I'd do that.

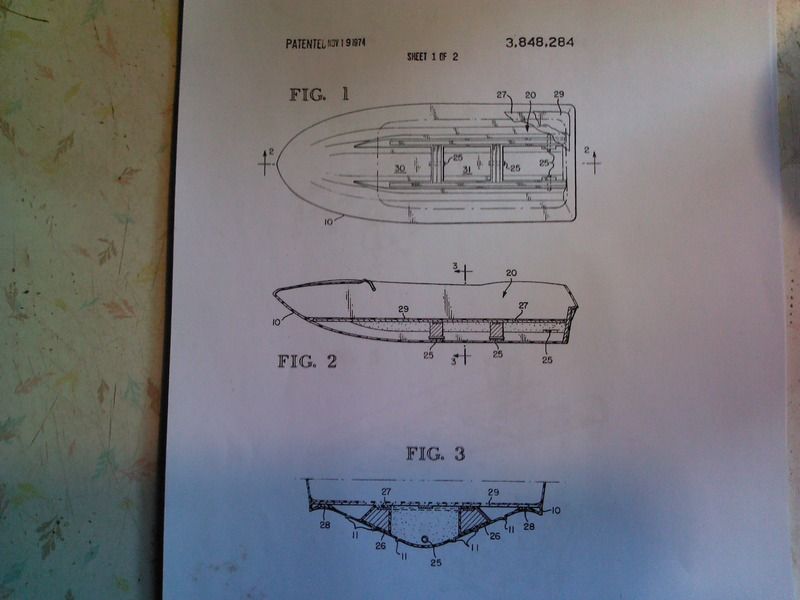

On the floor, it appears that either the floor was designed with a slight slope from each stringer to the outside edge, maybe to help drain off water, or the hull has sagged somehow to create the slope. Does anyone know if the slope was designed that way in these Reinells?

IF it's supposed to be flat, how do I remedy this? Would there be an issue if I didn't remedy it and installed a new floor with the slope?

Thanks in advance!

First, a shot of the boat...

The exterior of the cracks...

The interior of the cracks...

The areas of the floor that I cut the access holes...

So, ok, here come the questions...

On the exterior where the cracks are, the fiberglass has been pushed in creating a depression around the cracks. Does anyone think I could get away with just building up the depression with glass on the exterior and reinforce on the interior, or should I cut the whole thing out and start from scratch? There's a bit of an issue with cutting the whole thing out because of the way the stringers were done in this boat. There appears to be a foam support for them as seen in the interior shots. I would expect that if I were to cut the cracks out, I would have to replace the foam as well. Not quite sure how I'd do that.

On the floor, it appears that either the floor was designed with a slight slope from each stringer to the outside edge, maybe to help drain off water, or the hull has sagged somehow to create the slope. Does anyone know if the slope was designed that way in these Reinells?

IF it's supposed to be flat, how do I remedy this? Would there be an issue if I didn't remedy it and installed a new floor with the slope?

Thanks in advance!

Last edited: